Our Plastic Crusher Blades can be customized to meet your specific requirements:

-

Blade Dimensions:

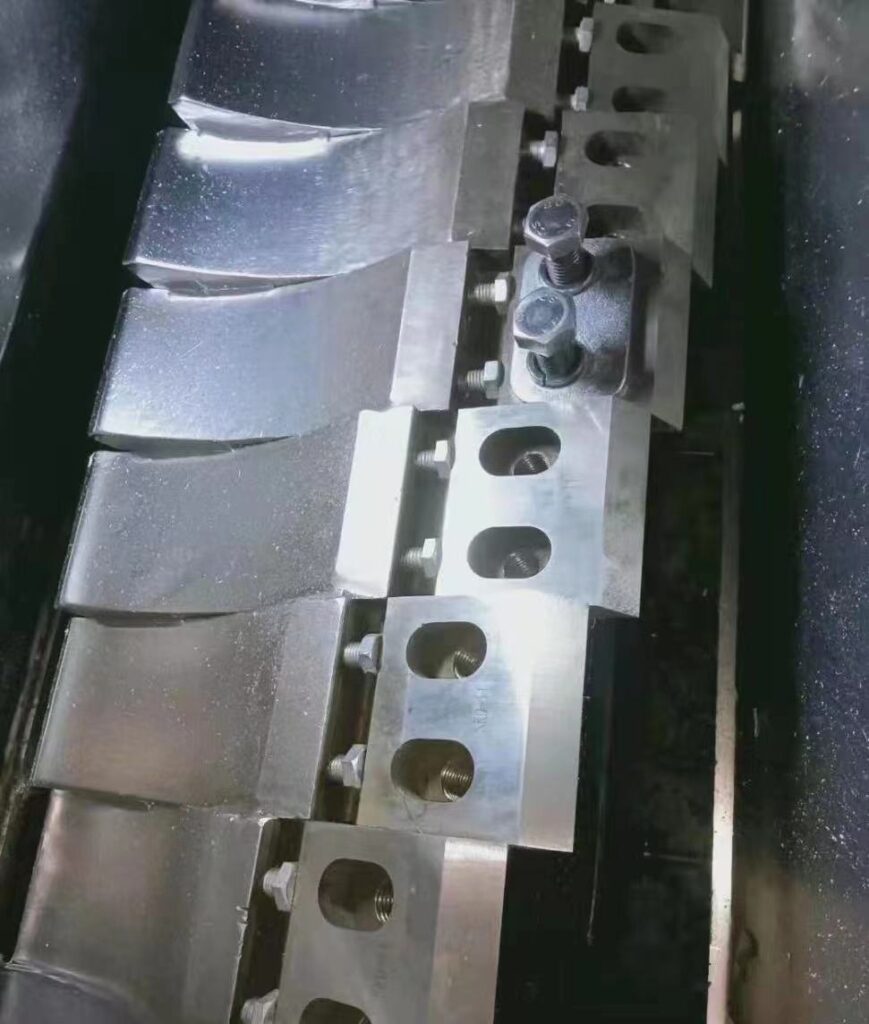

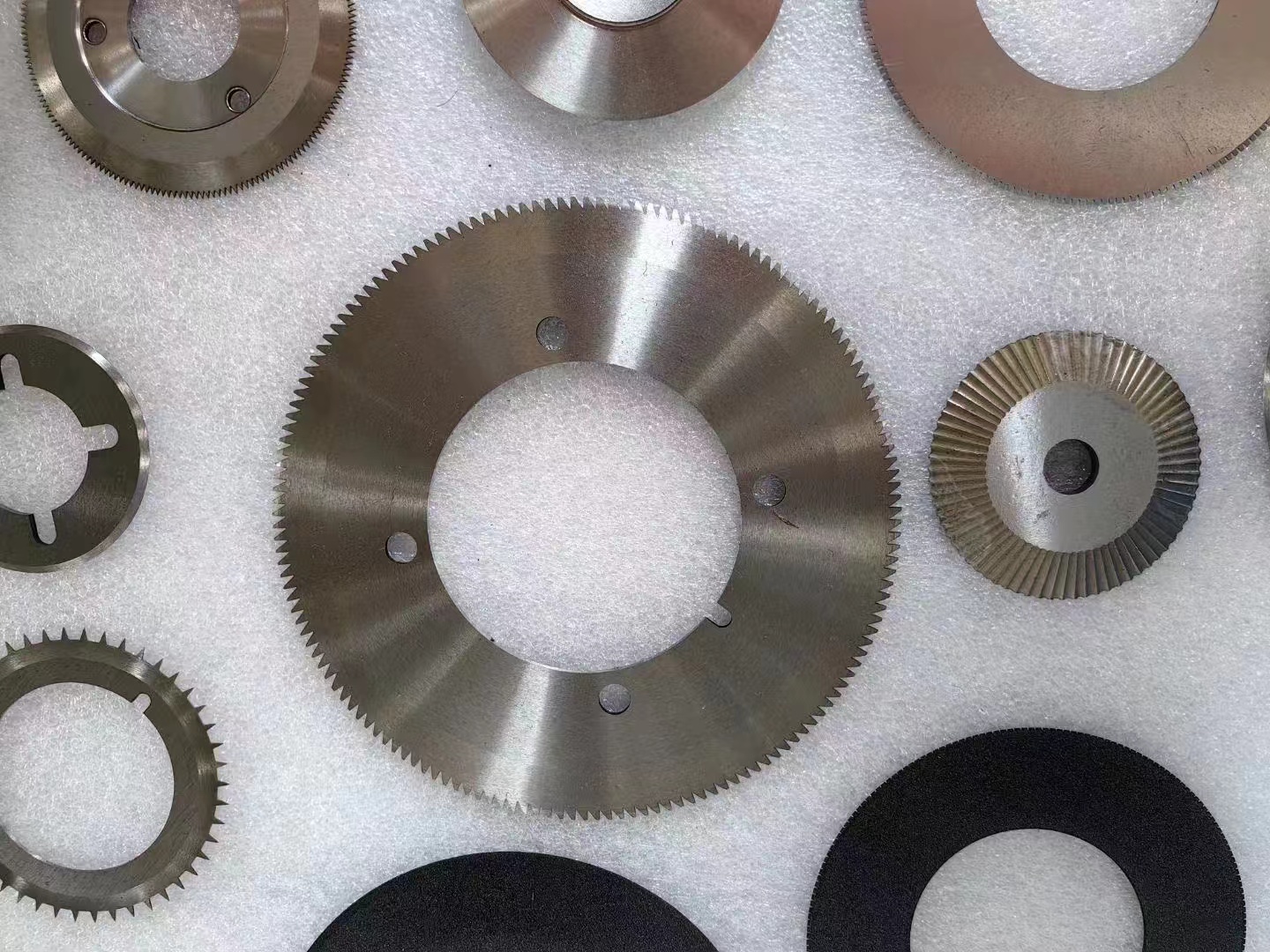

- Circular Blades: Diameter, thickness, and width can be adjusted.

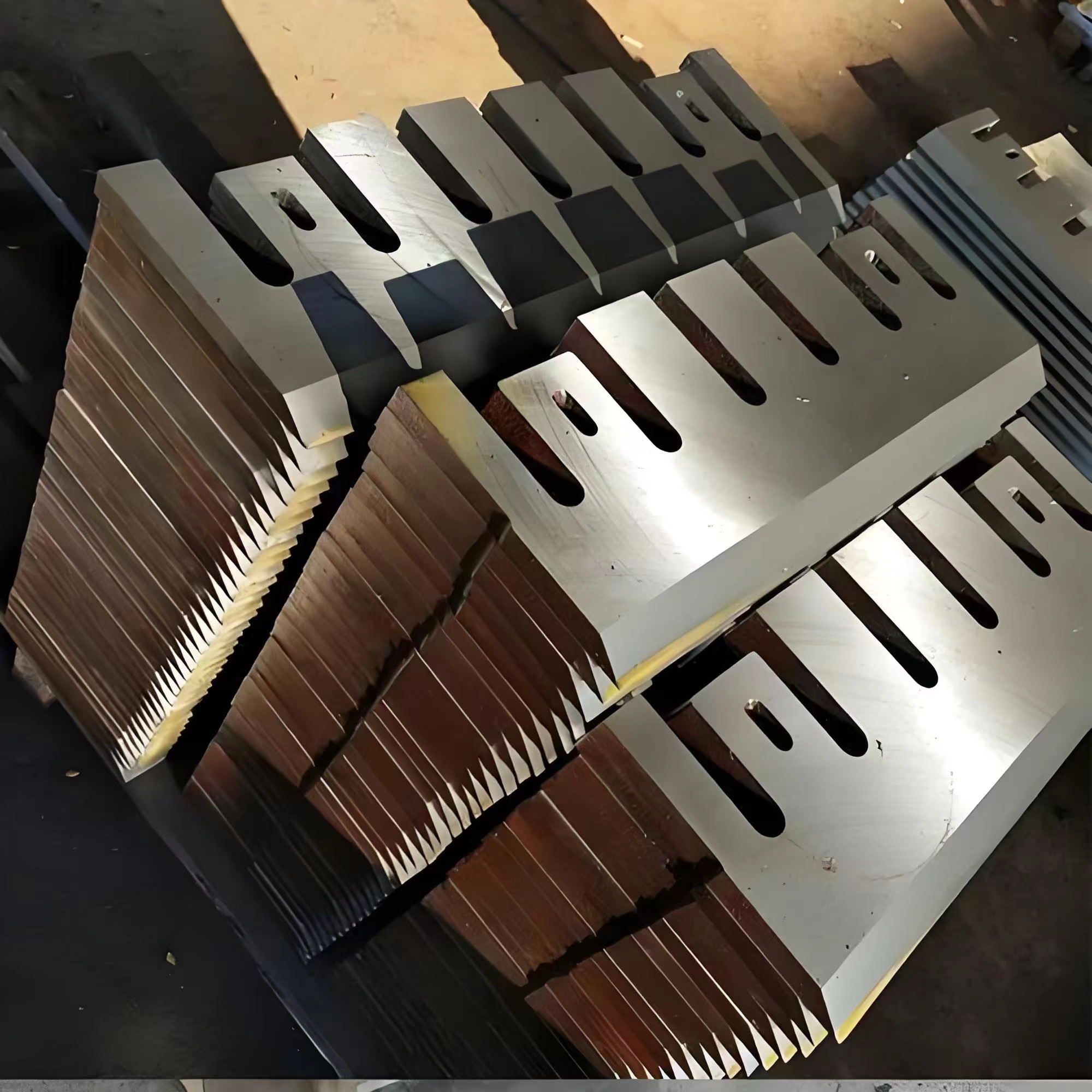

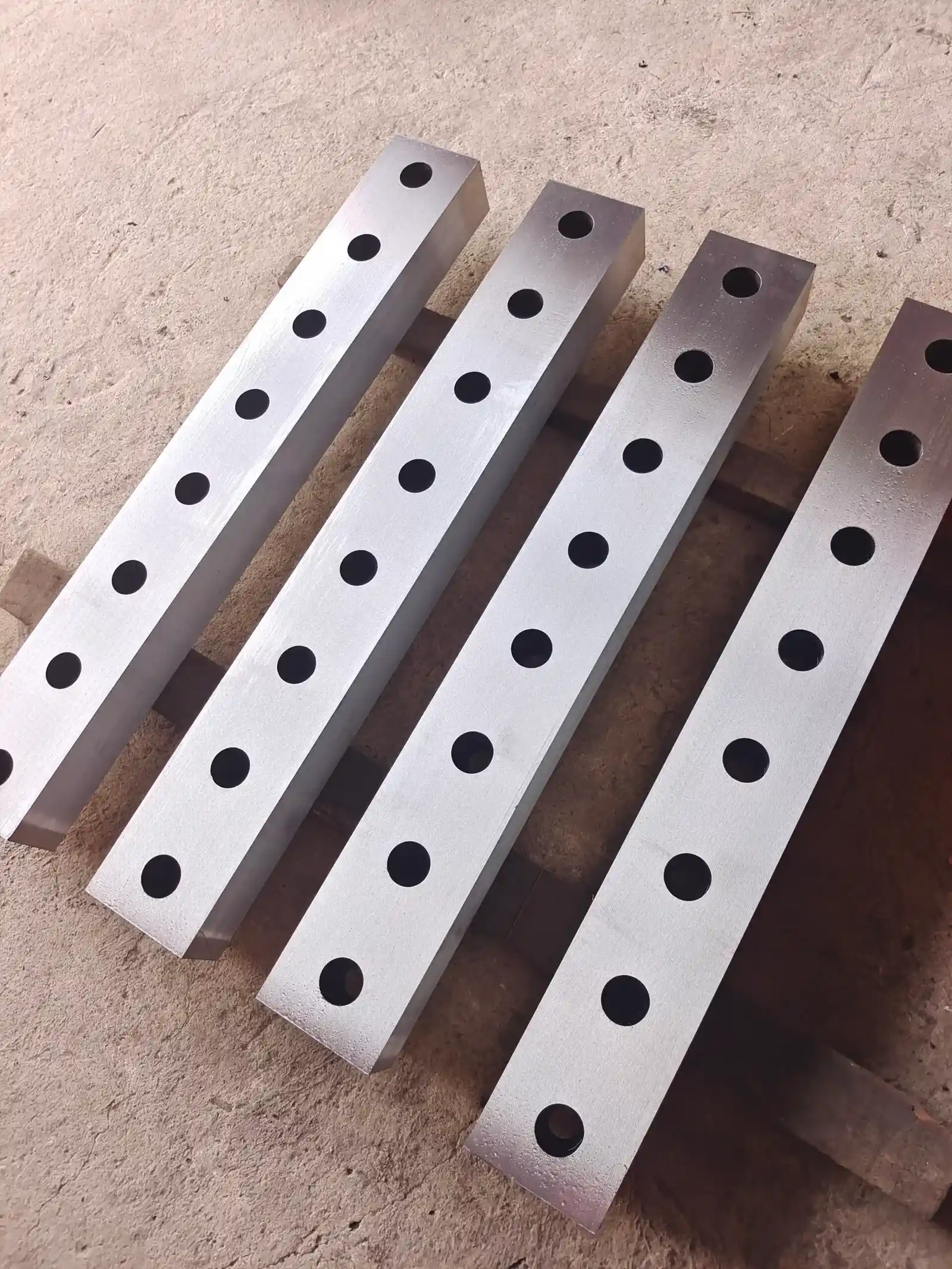

- Straight Blades: Length, width, and thickness can be customized.

-

Materials:

- High-Speed Steel (HSS): Suitable for applications requiring high heat resistance and durability.

- Tungsten Carbide: Ideal for abrasive materials due to its extreme hardness and wear resistance.

- Stainless Steel: Corrosion-resistant and maintains edge sharpness, perfect for clean cuts.

-

Edge Profiles:

- Standard Edge: Suitable for general-purpose cutting.

- Razor-Sharp Edge: For applications requiring extremely fine cuts.

- Serrated Edge: For gripping and tearing through tougher materials.

-

Coatings:

- Titanium Nitride (TiN): Reduces friction and enhances wear resistance.

- Diamond-Like Carbon (DLC): Provides additional hardness and reduces wear.

- Chrome Plating: Offers corrosion resistance and improves surface finish.

Customization Process

- Consultation: Discuss your specific needs and operational requirements with our technical team.

- Design Submission: Provide detailed specifications or drawings outlining your desired blade configuration.

- Prototype Review: We will create and send prototypes for your review and approval.

- Quality Assurance: Each custom blade undergoes rigorous testing to ensure it meets our high standards.

- Production and Delivery: Upon approval, we proceed with mass production and deliver the blades securely packaged in sturdy wooden boxes with protective plastic film.

By offering these customization options, we ensure that our Plastic Crusher Blades are tailored to your exact specifications, providing optimal performance and reliability in your plastic recycling operations.