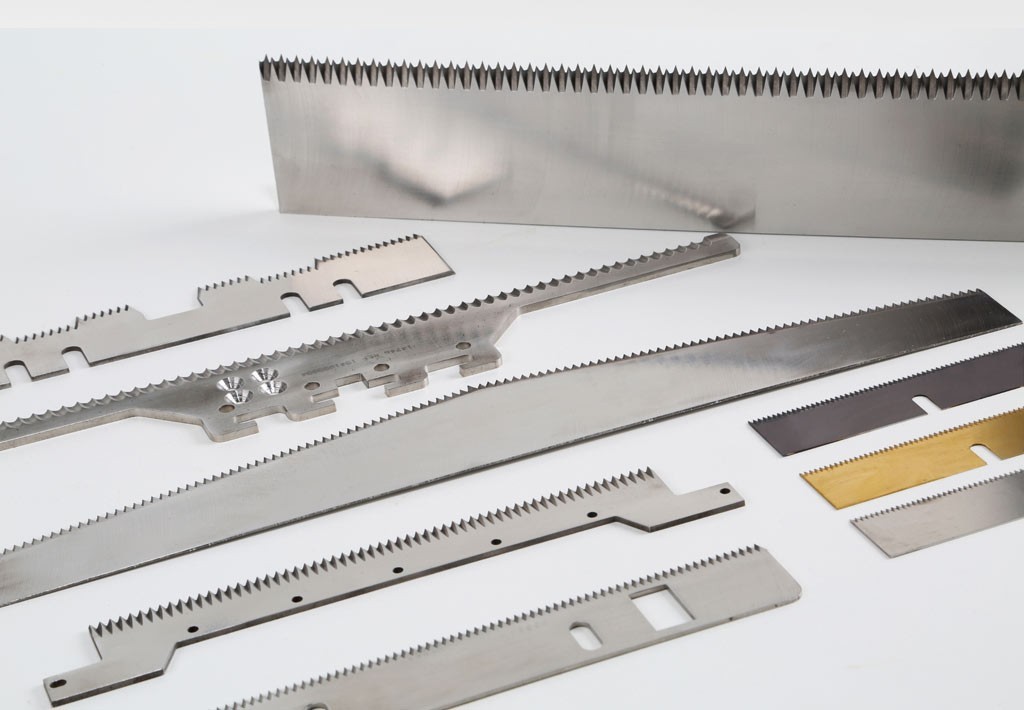

Packaging machine knives are specialized cutting tools used in automated packaging systems to perform various tasks such as slicing, sealing, and cutting packaging materials. They come in various shapes, sizes, and materials, depending on the type of packaging machine and the materials being processed. Whether used in tea packaging machines, food packaging lines, or general industrial applications, these knives are designed for durability and precision.

Types of Packaging Machine Knives

There are several types of knives for packaging machines, each designed for a specific function:

- Straight Knives:

- These knives are commonly used for straight cuts on packaging materials such as films and foils. They provide a clean cut and are widely used in industries like food packaging.

- Rotary Knives:

- Rotary knives are circular blades that rotate at high speeds. These knives are often used for cutting flexible packaging materials and are perfect for high-speed production lines, such as in tea packaging machines.

- Perforating Knives:

- Perforating knives are designed to create small holes or slits in packaging material. This type of knife is often used when a tearable package is required, such as in blister packaging or certain food products.

- Scissor Knives:

- These knives are designed like scissors and are used for cutting flexible materials. They are ideal for cutting both thin and thick films, making them versatile in packaging machinery.

- Slitting Knives:

- Slitting knives are used to cut wide rolls of material into narrower strips. They are typically used in the tea packaging machine and film packaging lines.

Applications of Packaging Machine Knives

The use of industrial packaging machine knives spans across various sectors, and each industry has unique requirements for cutting tools. Here are a few key applications:

1. Food Packaging

Packaging knives are widely used in food packaging machinery, where precision and hygiene are paramount. Knives for food packaging help cut products such as snacks, meats, and produce, and they are built to handle both dry and wet conditions. Tea packaging machines, for example, require sharp and precise knives to cut tea bags and pack them into boxes or pouches.

| Food Item | Knife Type | Function |

|---|---|---|

| Snacks and chips | Straight knives | Cutting and trimming snacks |

| Meat products | Rotary knives | Slicing through meat packaging materials |

| Tea bags | Perforating knives | Creating perforations for easy tearing |

2. Consumer Goods Packaging

In the packaging of consumer goods, knives play an essential role in efficiently cutting plastic films, paper, and cardboard. Packaging machines in this sector often deal with high-volume operations, where speed and durability are essential.

3. Pharmaceutical Packaging

For pharmaceutical products, precision is key. Packaging machine knives are used to cut blister packs, medical packaging films, and other items. The knives must meet high standards of cleanliness and cutting accuracy to ensure that the products are packaged safely and securely.

Materials Used in Packaging Machine Knives

The material used in manufacturing packaging machine knives is critical to their performance, especially when the knives are subject to wear and tear from continuous use. The following are common materials used:

- High-Carbon Steel: Known for its sharpness and durability, high-carbon steel is ideal for knives used in food packaging or in applications where a clean cut is essential.

- Stainless Steel: Stainless steel is commonly used due to its resistance to corrosion and staining, making it ideal for knives that come into contact with moisture and food products.

- Carbide-Tipped Blades: Carbide-tipped blades are used for cutting harder materials and are known for their extreme sharpness and wear resistance.

- Titanium-Coated Blades: Titanium coatings offer additional durability and resistance to corrosion, making them ideal for high-volume industrial settings.

Choosing the Right Knife for Your Packaging Machine

Selecting the appropriate knife for your packaging machine is crucial to optimizing performance. Key factors to consider include:

- Material to be Cut: The type of material being processed (e.g., plastic, foil, or paper) will influence the type of knife needed. For example, tea packaging machines require knives that can handle delicate paper and filter bags without damaging them.

- Speed of Production Line: The speed of the production line will determine whether a rotary knife or a straight knife is more suitable. High-speed lines often require rotary knives for consistent cuts.

- Durability: The durability of the knife is a critical factor in reducing downtime and increasing production efficiency. Knives made from carbide or titanium-coated materials can withstand long hours of operation without losing sharpness.

- Precision and Cleanliness: For industries such as food and pharmaceuticals, the knife must ensure precise cuts without contaminating the product.

Benefits of High-Quality Packaging Machine Knives

Investing in high-quality packaging knives can offer several benefits:

- Increased Efficiency: A sharp, well-maintained knife cuts through packaging materials with ease, leading to faster processing times and reduced cycle times.

- Reduced Downtime: High-quality knives require less frequent replacement or sharpening, reducing machine downtime and improving overall productivity.

- Consistency: Precision knives ensure consistent cuts, leading to uniform packaging and higher-quality products, which are critical in food and pharmaceutical industries.

- Cost Savings: Although high-quality knives may come at a higher initial cost, their longevity and performance can lead to significant cost savings in the long run.

Conclusion

Packaging machine knives are indispensable tools in the industrial packaging process, ensuring products are cut and sealed efficiently. From tea packaging machine knives to slitting knives used in the packaging of consumer goods, the right knife can improve production rates, reduce downtime, and increase overall product quality. When selecting the correct knife for your system, factors such as material, production speed, and durability must be carefully considered to ensure optimum performance and longevity.

By investing in the right types of knives and maintaining them properly, industries can significantly enhance their packaging efficiency, ensuring that their operations run smoothly and their products are delivered with the highest standards of quality.