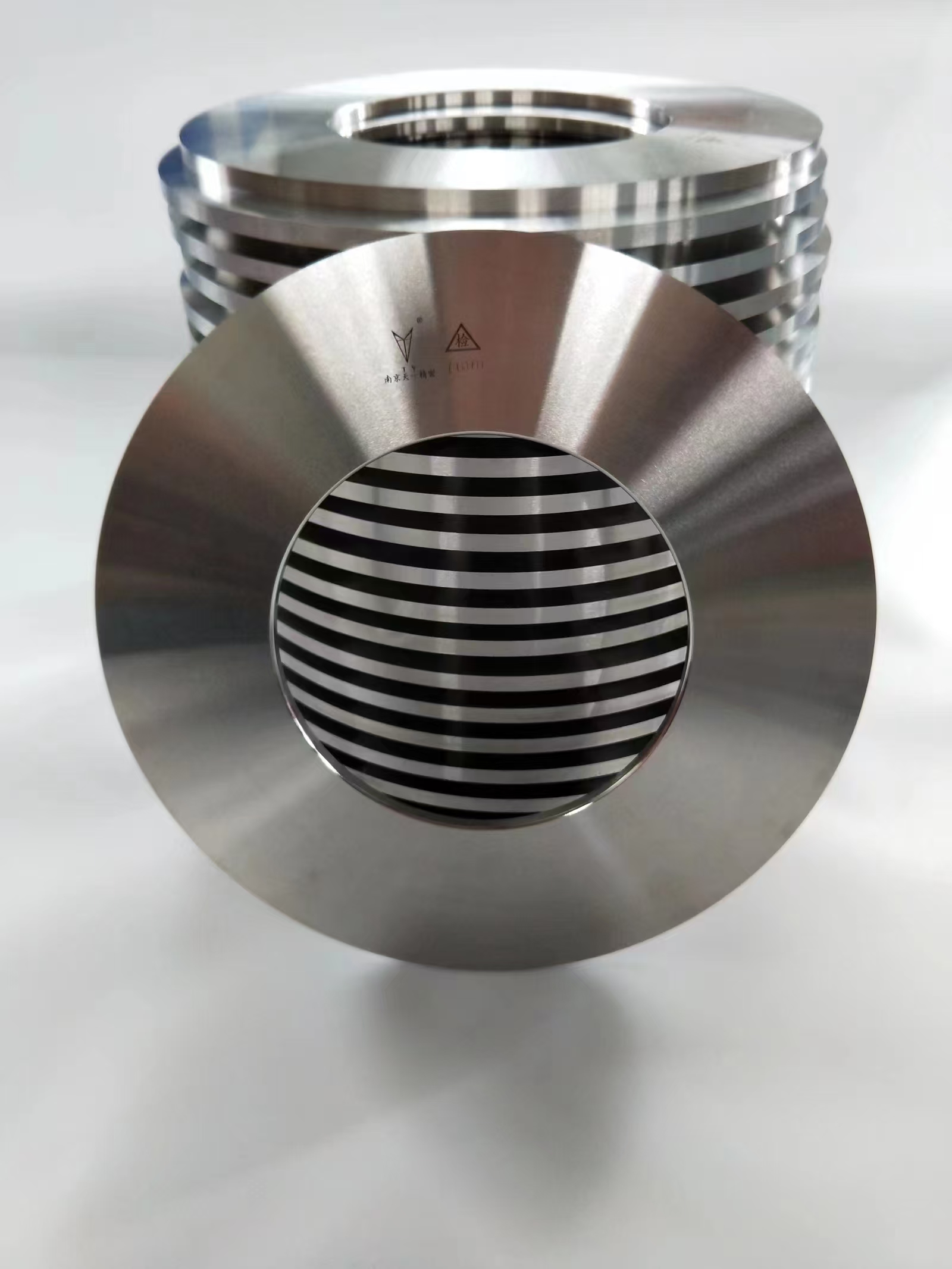

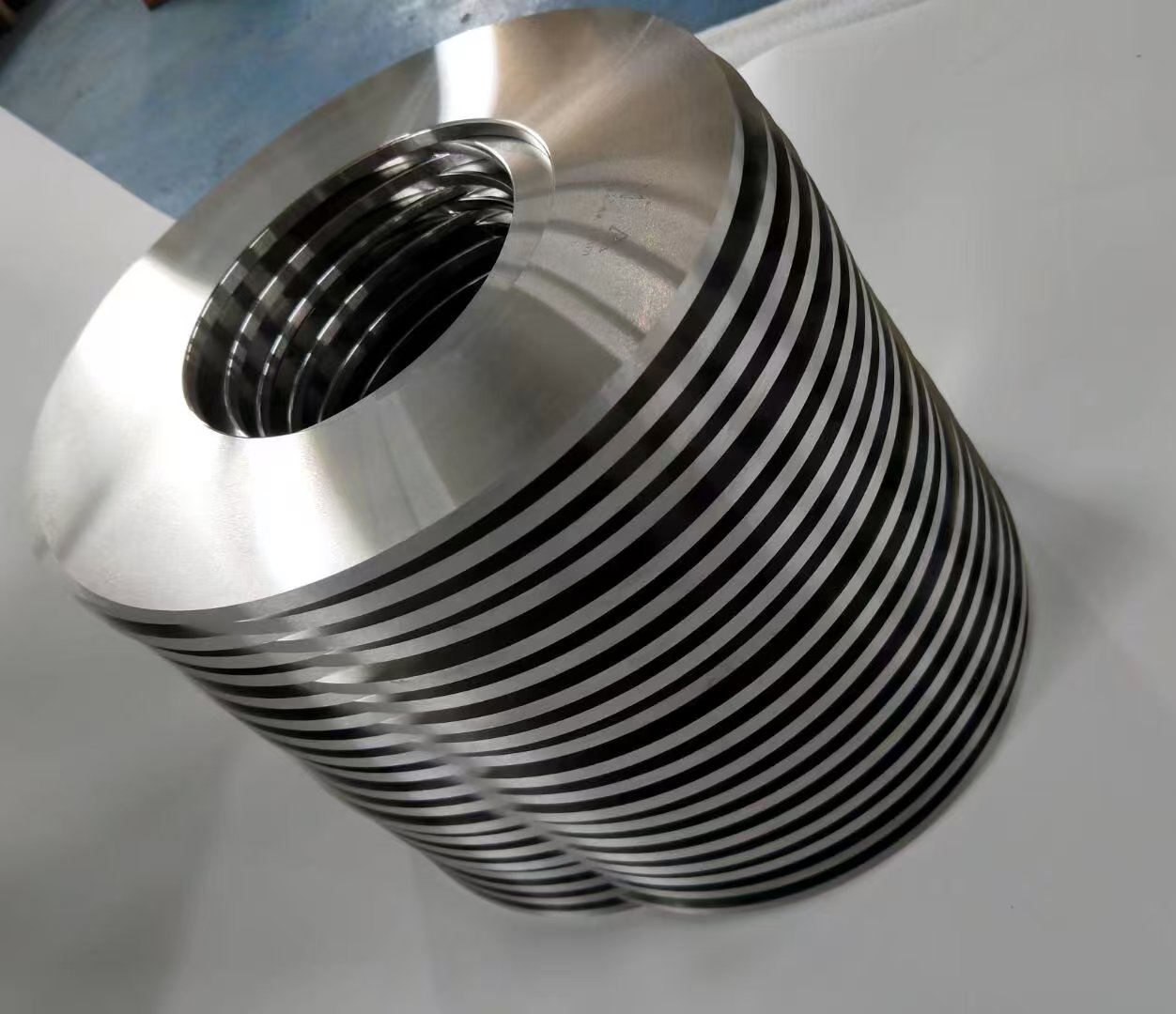

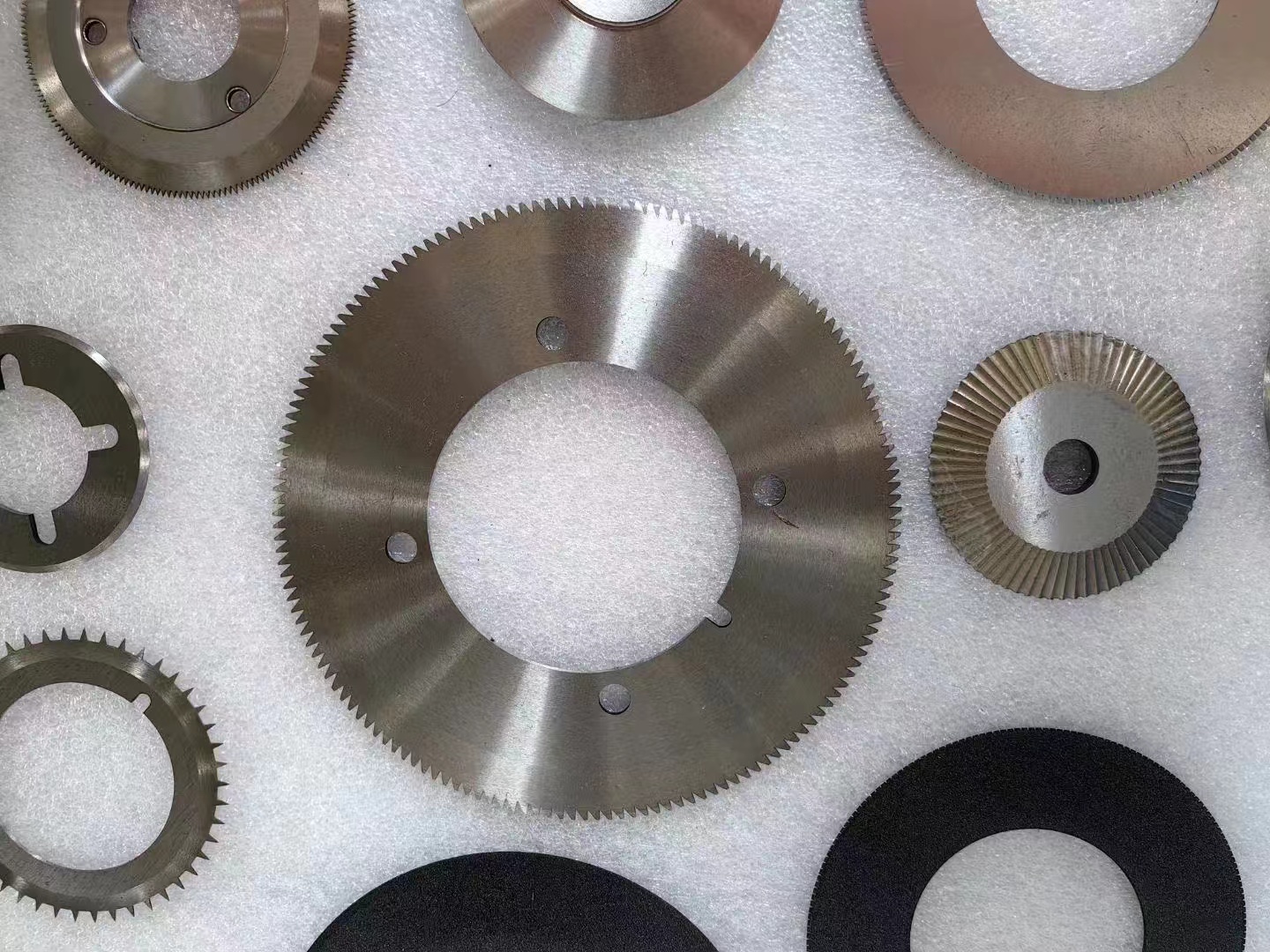

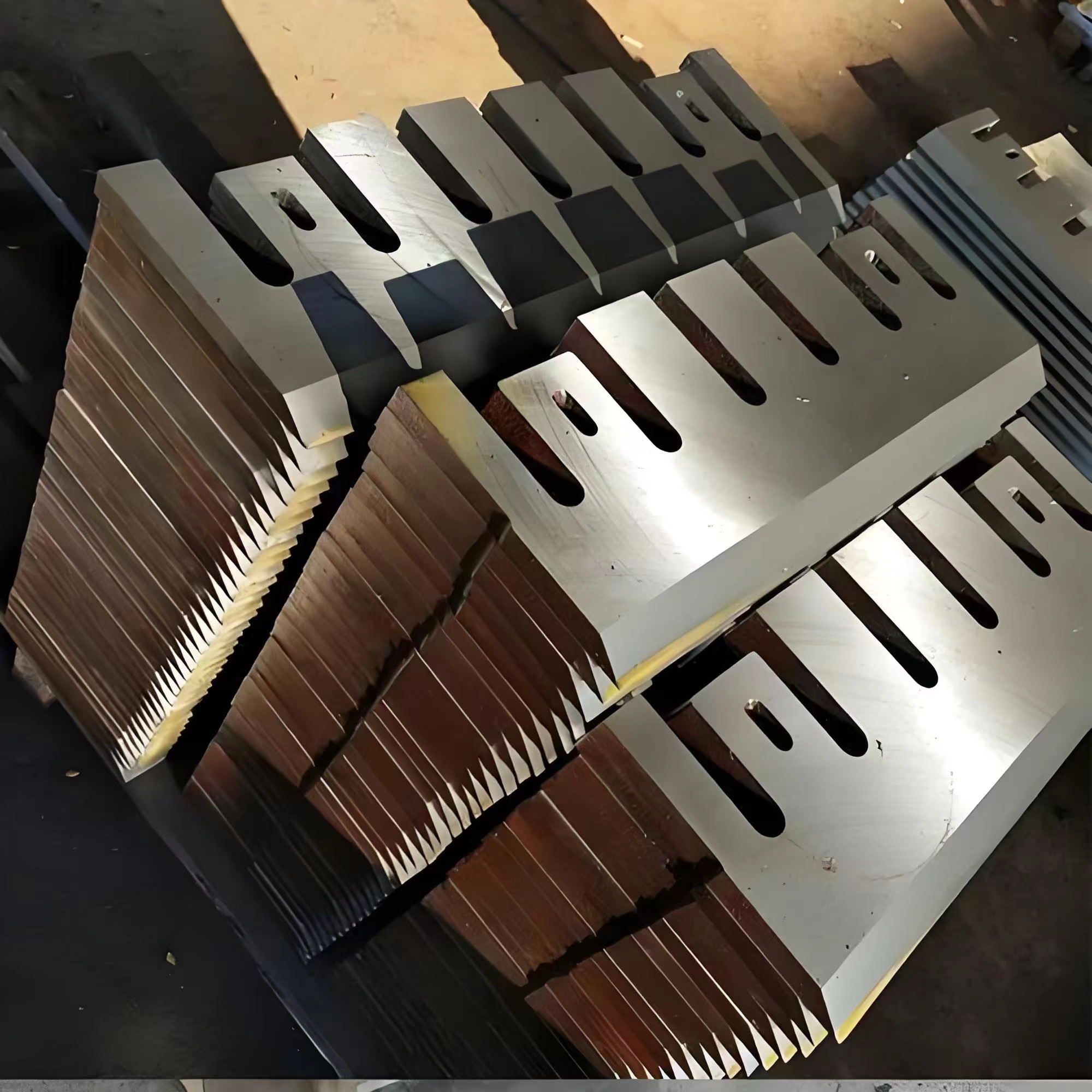

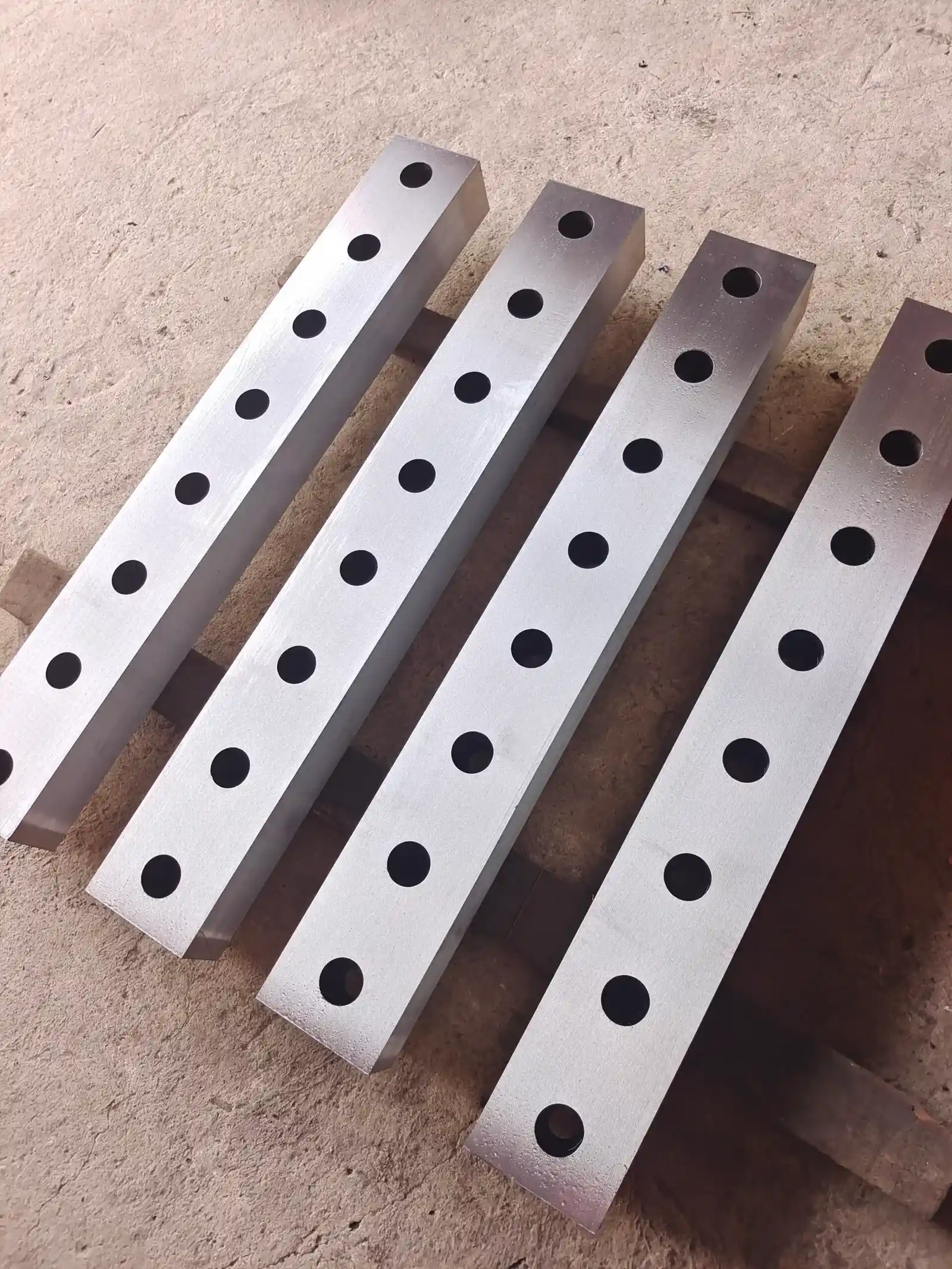

Metal Slitting Knives are high-precision circular blades designed for efficient slitting of thin metal sheets. Suitable for a wide range of industries including steel manufacturing, pipe production, non-ferrous metal processing, and more, these durable tools ensure accurate cuts and reliable performance in demanding industrial applications.

Our Metal Slitting Knives are crafted from high-quality materials selected for their durability and performance. Typically, these include options such as: High-Speed Steel (HSS): Known for its ability to retain sharpness at high temperatures, making it ideal for high-speed cutting operations. Tungsten Carbide: Offers exceptional wear resistance and toughness, suitable for applications requiring extended blade life and resistance to abrasion. Tool Steel: Provides a good balance between hardness and toughness, suitable for general-purpose slitting applications. Please specify your preferred material or consult with our experts to determine the best option for your specific application. We can also apply specialized coatings such as titanium nitride (TiN) or diamond-like carbon (DLC) to further enhance the blade's performance and durability.