Food processing knives are specialized tools made of stainless steel to ensure they are rust-resistant, non-toxic, and food-safe. They are designed for various food processing tasks, including cutting, slicing, and carving.

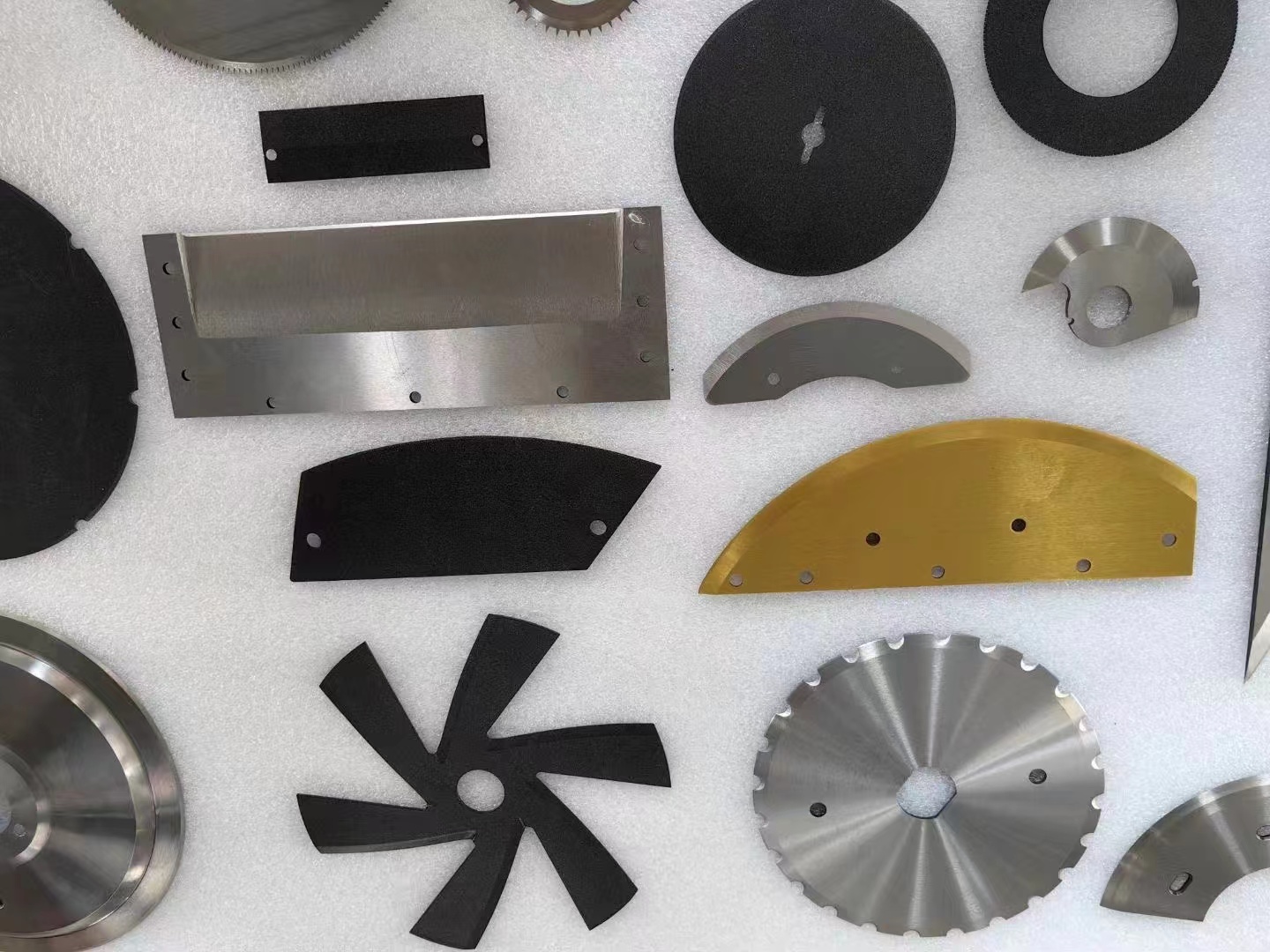

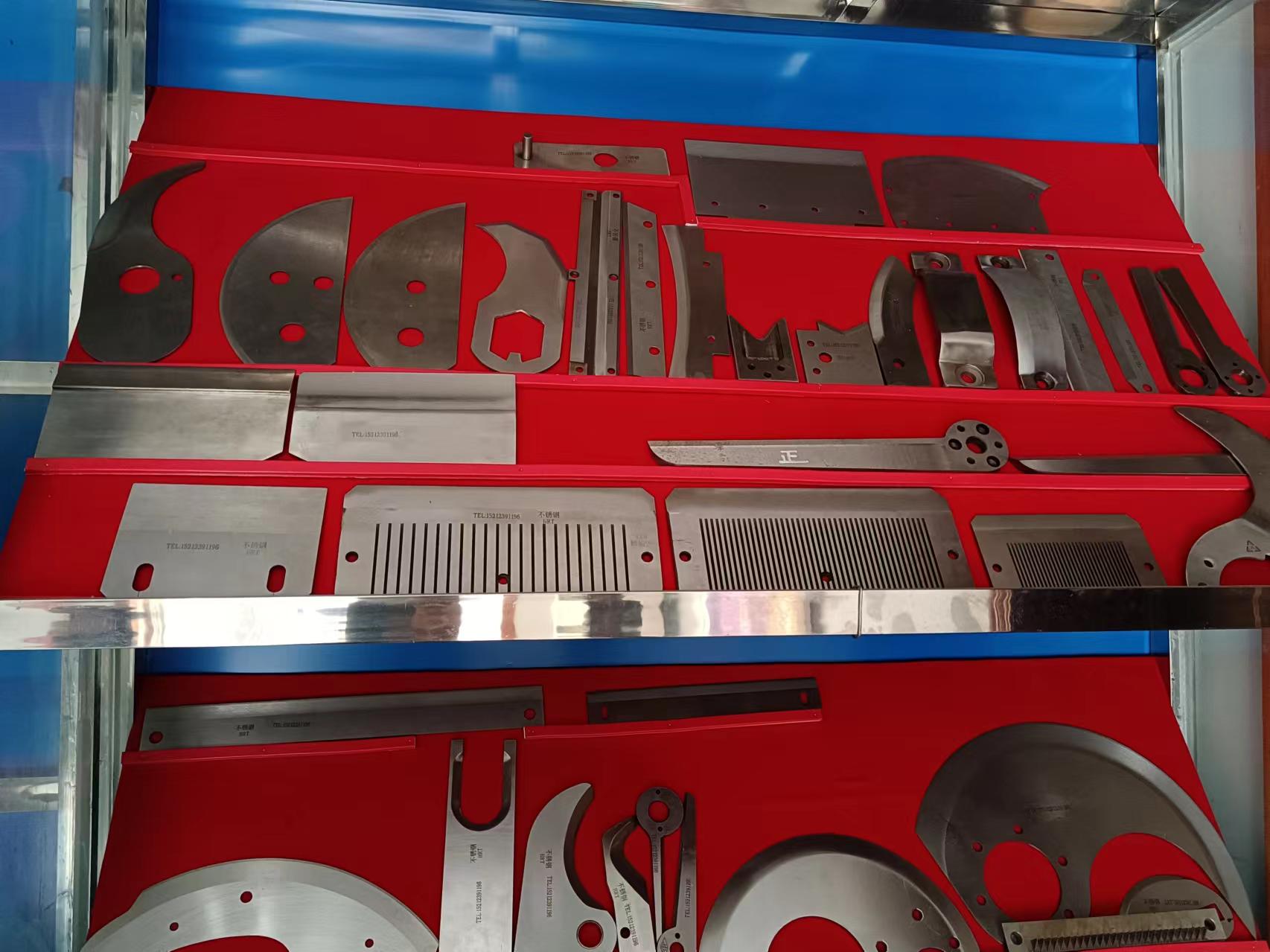

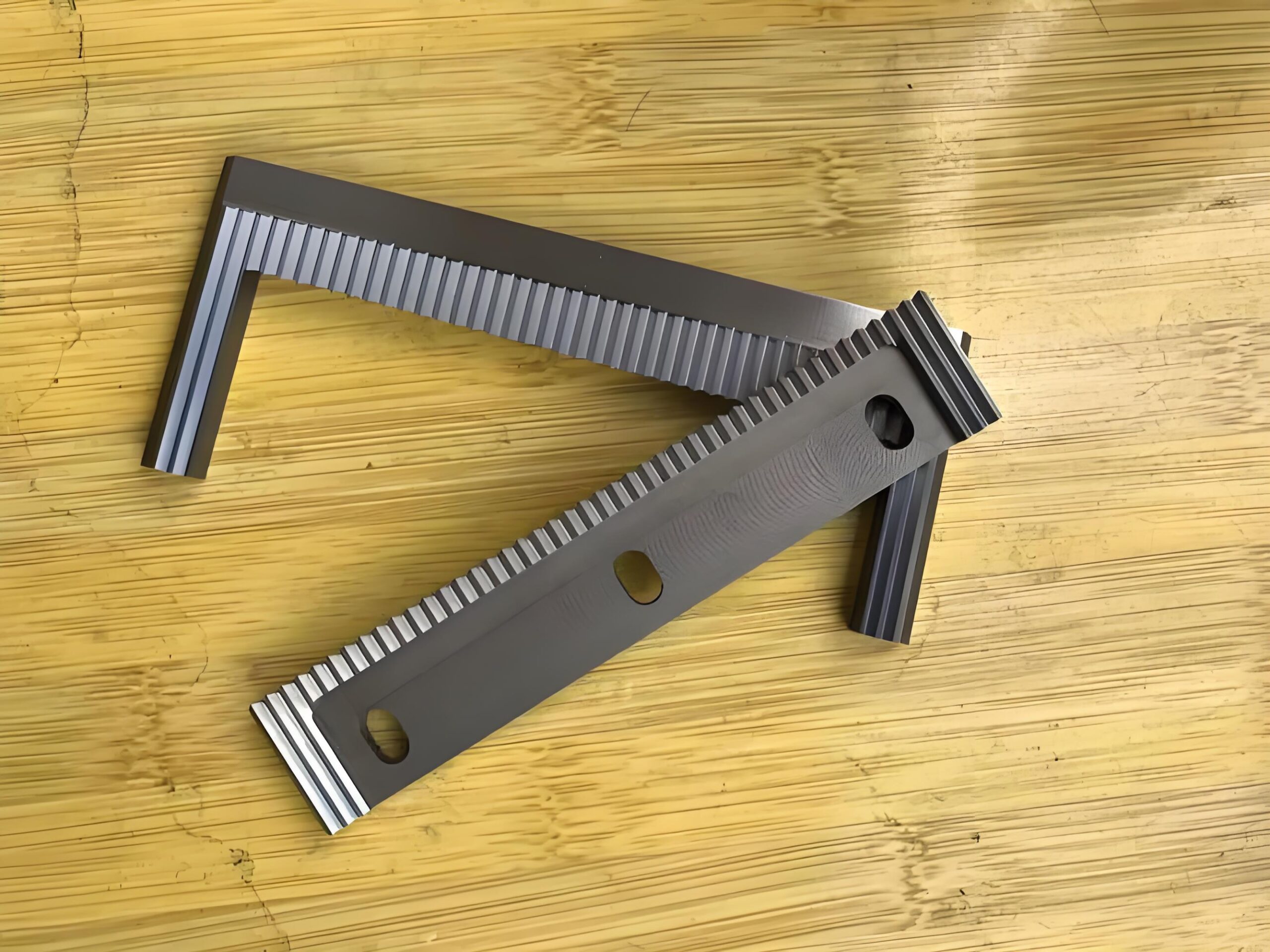

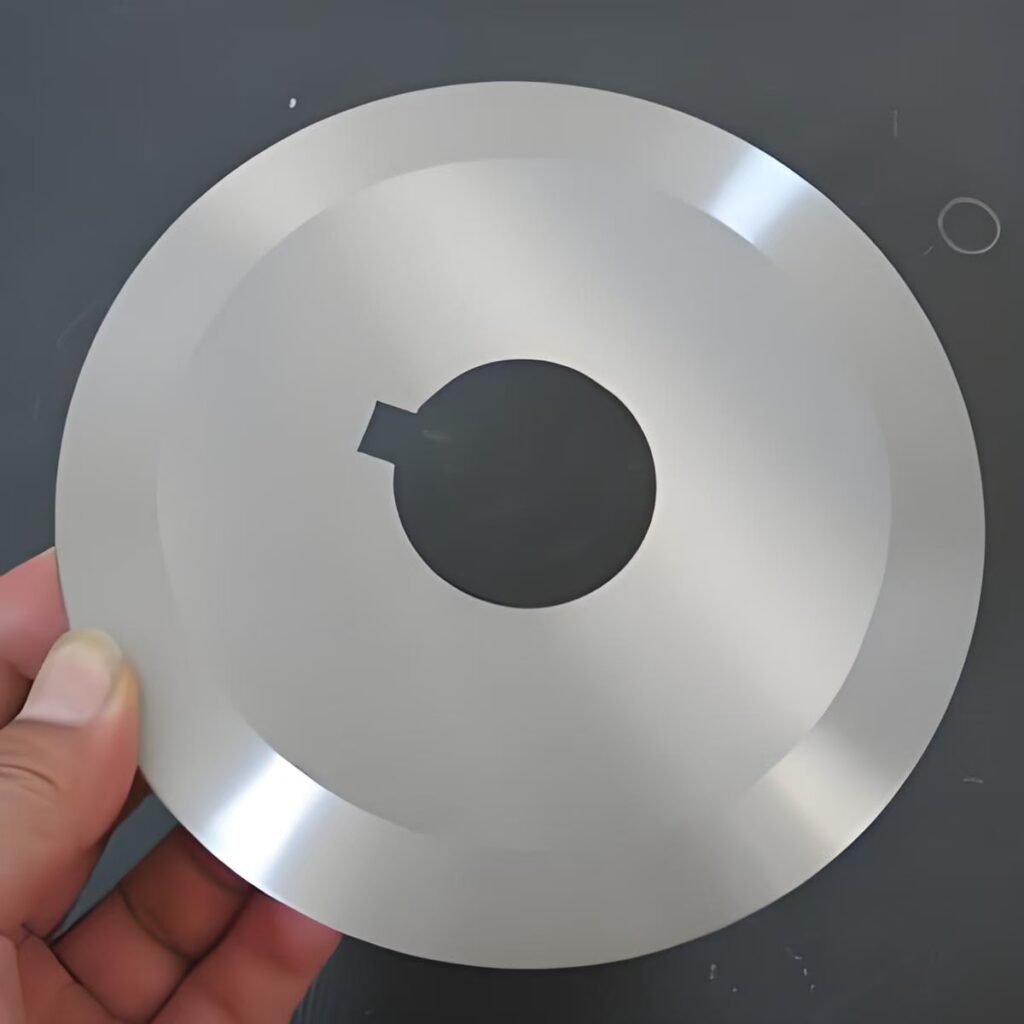

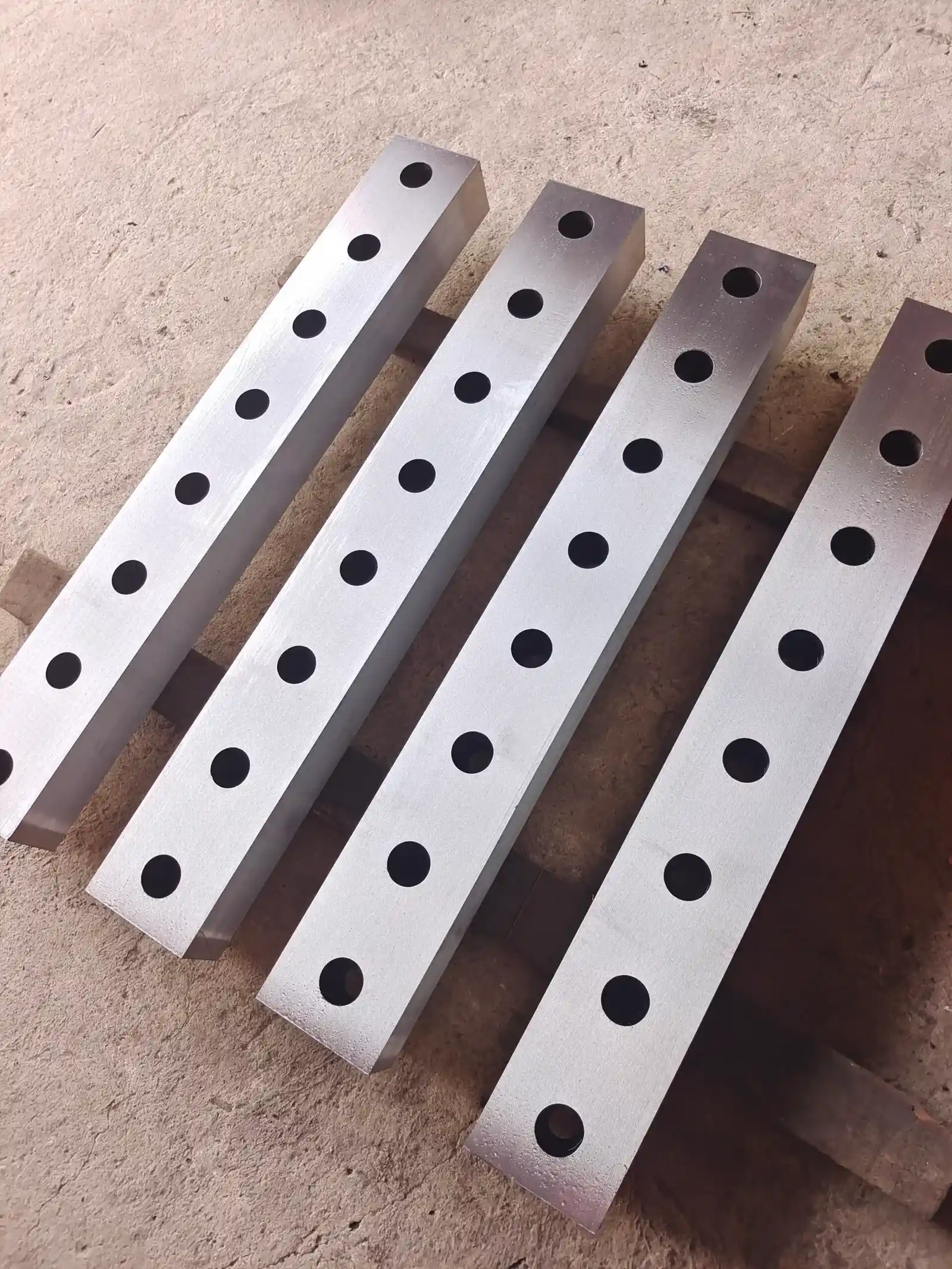

- Food Blades: Used for cutting and slicing, suitable for pastry and bread processing.

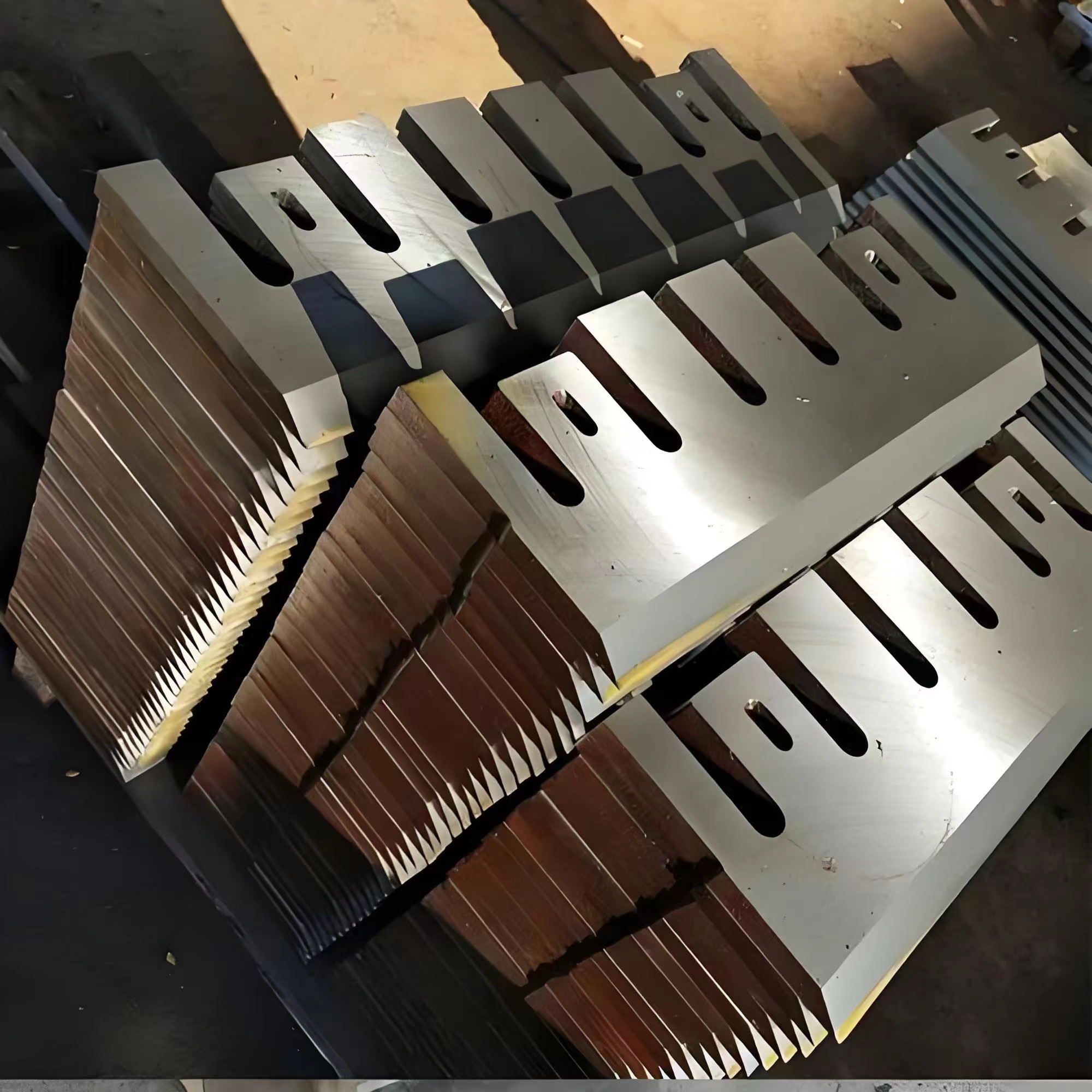

- Food Carving Knives: Known as pull carving knives, they offer fast and smooth carving, ideal for decorative food items.

- Kitchen Knives: Available in Chinese, Western, and Japanese styles, these knives are versatile and precise, essential for various culinary tasks.

These knives are designed to meet strict food safety standards, ensuring both efficiency and hygiene in food processing.