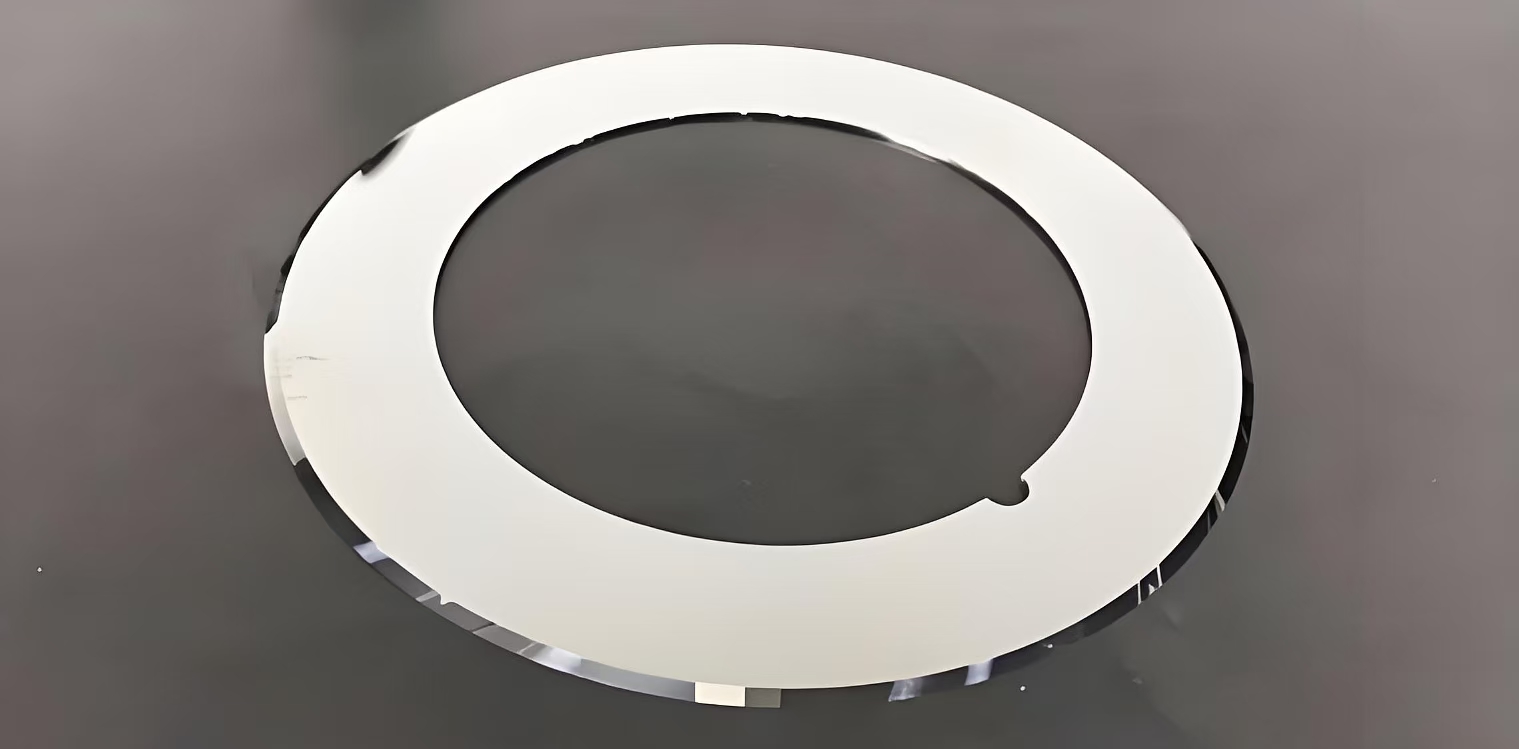

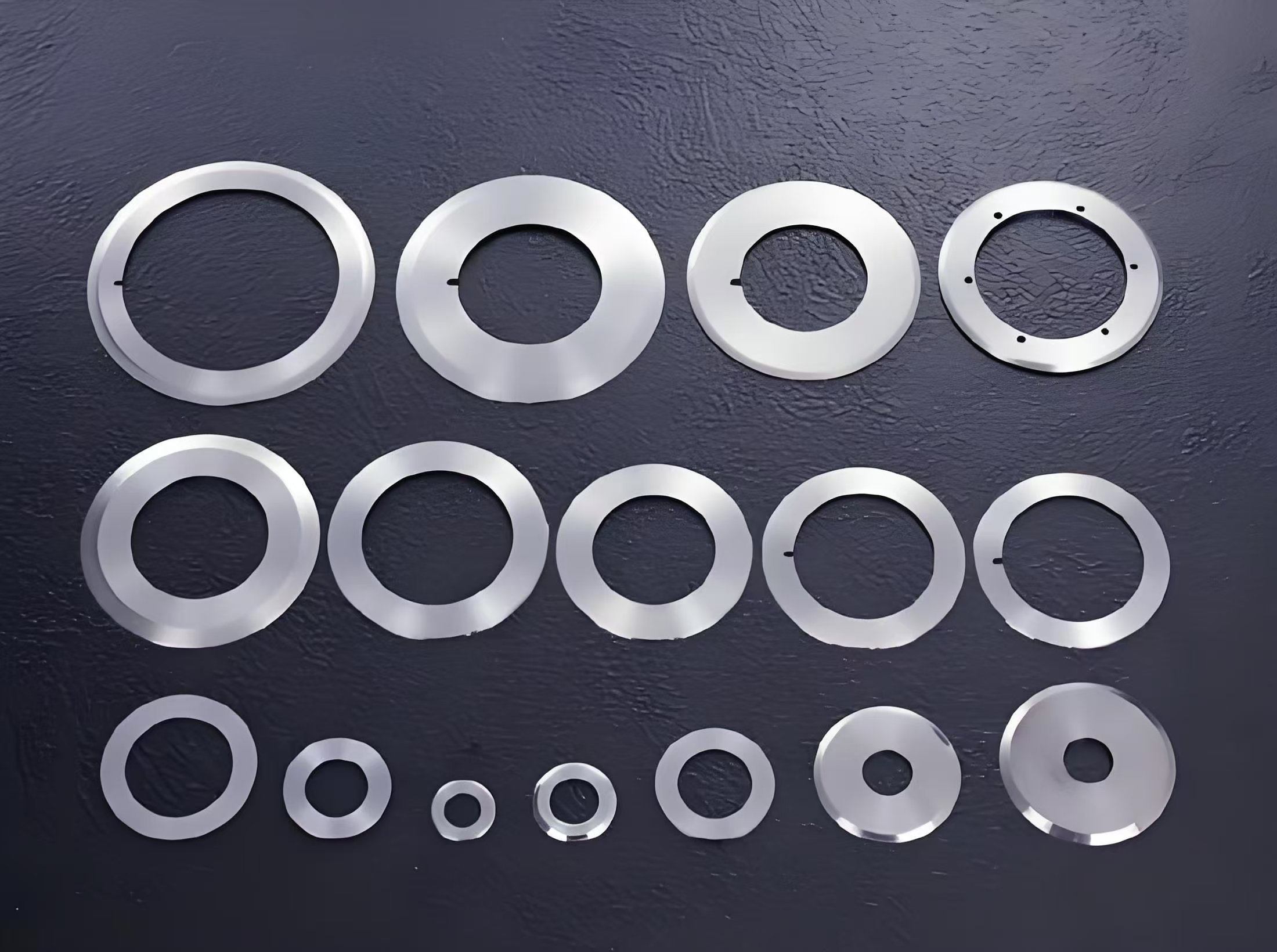

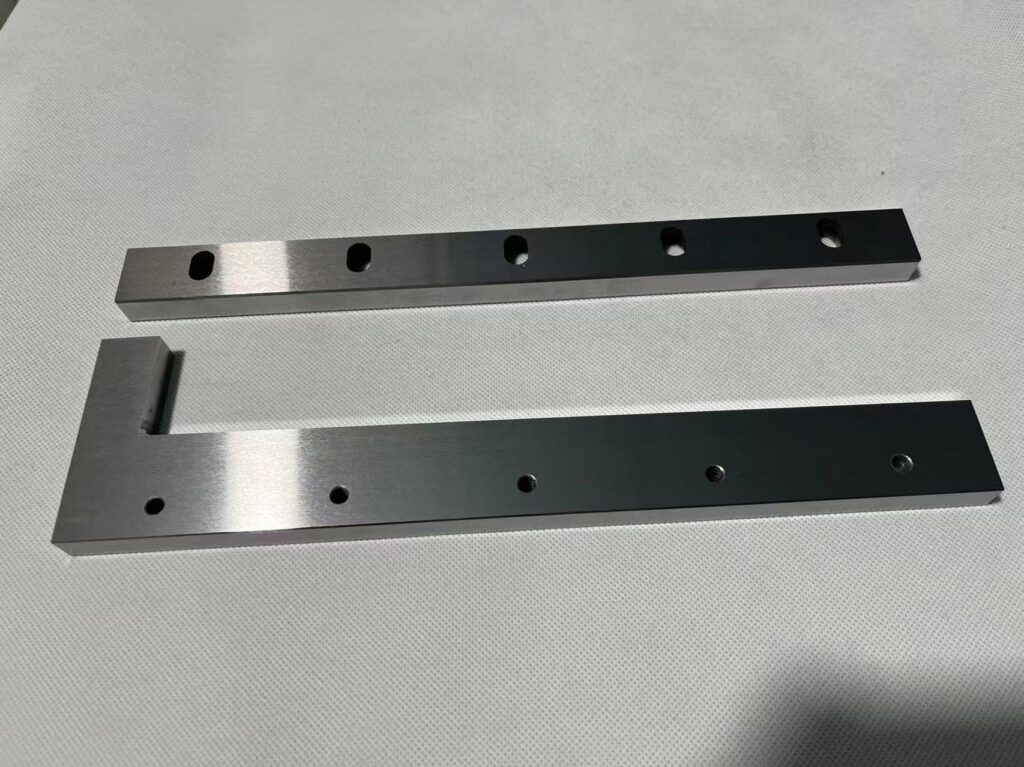

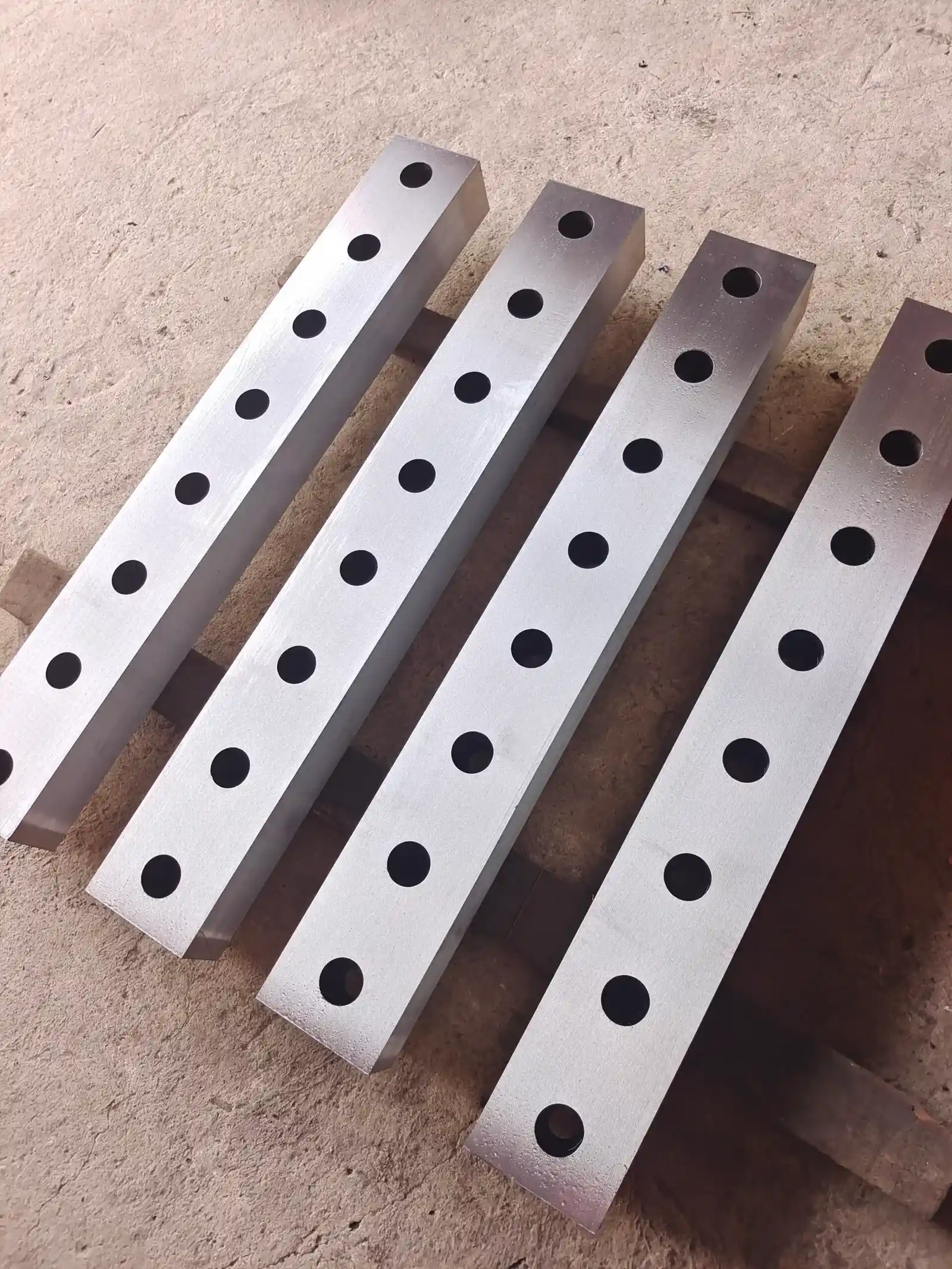

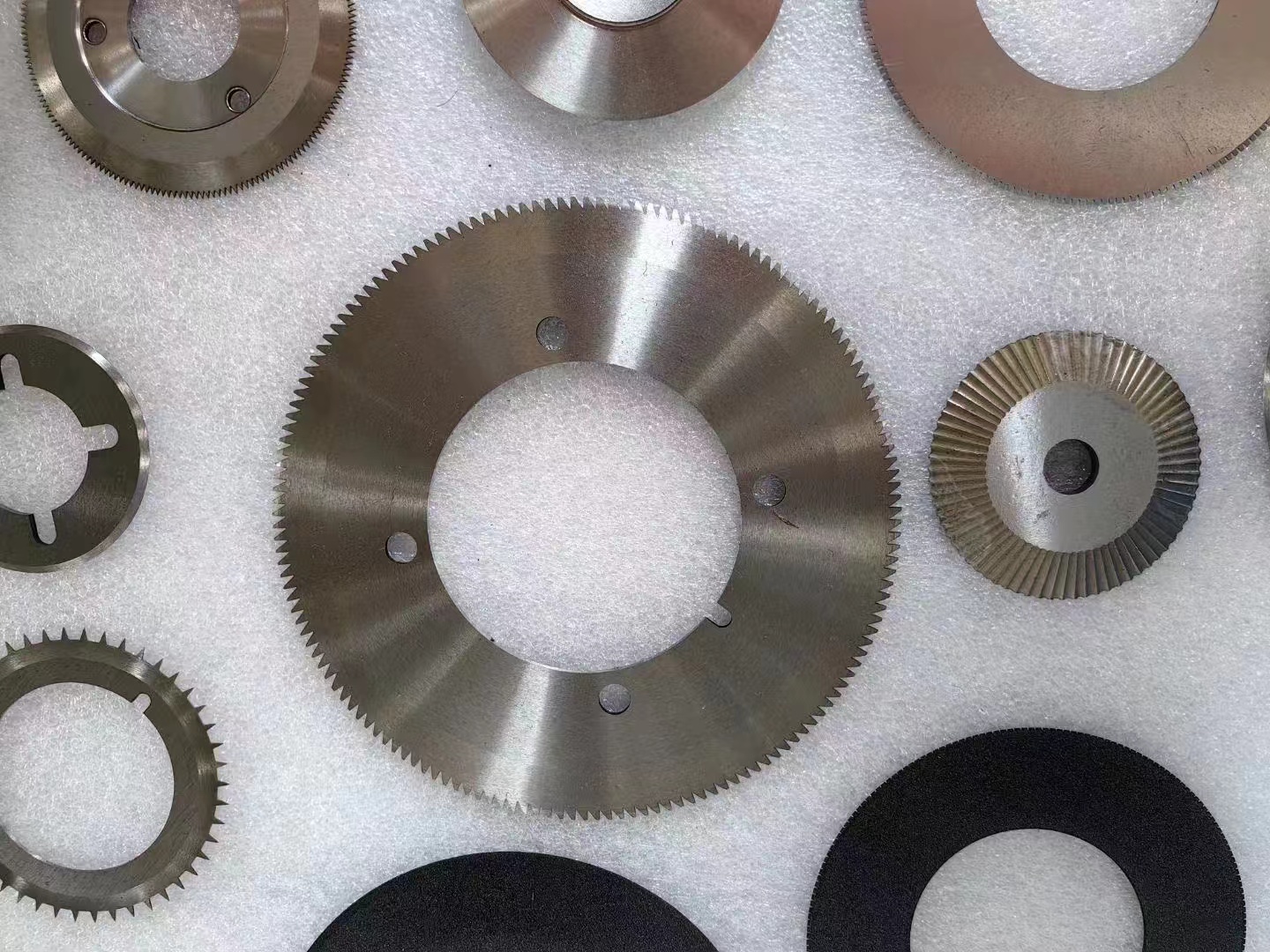

Elevate your metal foil processing with our versatile Metal Foil Cutting Tools, available in three distinct styles: straight blades for precise linear cuts, L-shaped blades for corner trimming and detailed work, and circular blades for accurate slitting and strip cutting. Crafted for durability and precision, these tools are essential for achieving clean edges and consistent results in both manual and automated settings.

When selecting materials for our Metal Foil Cutting Tools, we prioritize durability, sharpness retention, and suitability for cutting metal foils efficiently. Below are the typical materials used for different types of blades: Straight Blades & L-Shaped Blades For straight blades and L-shaped blades, commonly used materials include: High-Speed Steel (HSS): Known for its ability to retain sharpness even at high temperatures, HSS is ideal for continuous use in demanding environments. Tool Steel: Offers excellent wear resistance and toughness, making it suitable for applications where durability is key. Stainless Steel: Provides corrosion resistance and maintains edge sharpness, beneficial for clean cuts in various metal foils. Circular Blades Circular blades, designed for slitting operations, often utilize: Hardened Steel: Typically features a harder surface to withstand the stresses of continuous rotation and cutting action. Tungsten Carbide Tipped (TCT): For blades that need to cut through tougher materials, TCT provides enhanced wear resistance and sharpness retention. Ceramic: In some cases, ceramic may be used for its extreme hardness and ability to hold an edge for extended periods, though it is less common due to its brittleness. Coatings To further enhance the performance and lifespan of the blades, we may apply: Titanium Nitride (TiN): Provides a protective layer that reduces friction and increases wear resistance. Diamond-Like Carbon (DLC): Adds a thin, hard coating that improves the blade's hardness and reduces the likelihood of chipping or breaking. Chrome Plating: Offers corrosion resistance and improves the blade's surface finish. Each material selection is made based on the intended application, the type of metal foils being cut, and the operating conditions of the machinery. Our engineering team can help determine the best combination of materials and coatings to optimize tool performance for your specific requirements.