In the world of manufacturing, precision and efficiency are key to ensuring that production lines run smoothly and the final product meets the highest standards. One critical aspect of achieving this level of quality in many industries is the use of cutting machine knives. These knives are designed to provide precise, consistent cuts in various materials, whether it’s fabric, wood, paper, or plastic. In this article, we will explore the different types of cutting machine knives, including cloth cutting knives for Eastman machines, CNC 4 knives V-groove cut machines, dowel machine cutting knives, glitter cutting machine knives, and more. We’ll also look at their applications and importance in various industries.

What Are Cutting Machine Knives?

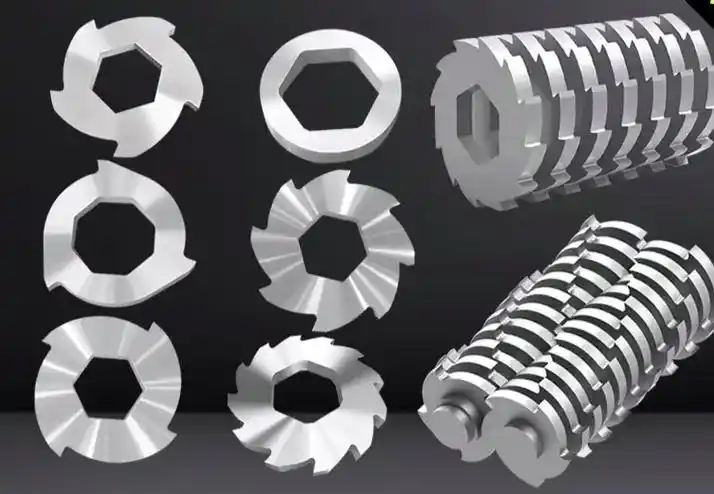

Cutting machine knives are tools used in industrial cutting machines to slice, shape, or trim materials to specific dimensions. These knives are made from high-quality materials such as high-carbon steel, stainless steel, or carbide to ensure durability, precision, and resistance to wear. Depending on the application, they come in various designs and sizes to accommodate different types of machines and cutting tasks.

Types of Cutting Machine Knives

Let’s dive deeper into the specific types of cutting knives used in different industries, their applications, and why they are essential for achieving optimal results.

1. Cloth Cutting Knives for Eastman Machines

One of the most common types of cutting knives used in the textile industry is the cloth cutting knives for Eastman machines. Eastman machines are well-known for their ability to cut large rolls of fabric into patterns or shapes with high precision. The cloth cutting knives are designed to withstand the wear and tear of cutting through various fabric types, including delicate materials like silk and heavy-duty fabrics like denim.

Eastman machines typically use rotary knives or reciprocating knives, which offer smooth and efficient cutting. The cloth cutting knives are made from durable materials such as high-carbon steel or carbide, ensuring they stay sharp for a long time. Whether you're working with woven, knitted, or nonwoven fabrics, these knives are engineered to reduce fabric waste and improve cutting efficiency.

2. CNC 4 Knives V-Groove Cut Machine

In industries that require precision cutting of sheet metal, wood, or composite materials, the CNC 4 knives V-groove cut machine is an essential tool. This cutting machine utilizes a set of four knives to create V-shaped grooves in materials, which is commonly needed in industries like electronics, automotive, and cabinetry.

The CNC 4 knives V-groove cut machine operates through computer numerical control (CNC), which means the machine’s movements are automated and guided by software. This allows for high-precision cuts with minimal human intervention. The use of CNC knives ensures consistent groove quality, reducing the risk of errors or defects during production. These machines are perfect for industries that require clean, uniform grooves for parts that will later be assembled or welded.

| Type of Knife | Material | Common Applications |

|---|---|---|

| CNC V-Groove Knives | Carbide | Sheet metal, composite materials |

| Cloth Cutting Knives | High-carbon steel | Textile manufacturing, fabric cutting |

3. Dowel Machine Cutting Knives

In woodworking, dowel machine cutting knives are essential for shaping wood into uniform, cylindrical dowels. These dowels are widely used in furniture manufacturing, cabinet making, and even in the production of musical instruments. The precision and consistency of dowel machine cutting knives ensure that each dowel is smooth, round, and the correct size, reducing the need for additional finishing or sanding.

Dowel cutting knives are typically made from high-quality, hardened steel or carbide, which helps maintain their sharpness and effectiveness over time. This is especially important when cutting through dense hardwoods or materials that are prone to wear. Properly maintained knives allow manufacturers to produce large quantities of dowels quickly and efficiently, without compromising on quality.

4. Glitter Cutting Machine Knives

For the cosmetic and craft industries, precision is key when it comes to cutting glitter. Glitter cutting machine knives are designed to cut glitter sheets into small, consistent pieces, ensuring that each glitter particle is uniform in size. These knives are usually made of stainless steel or another durable material that resists corrosion from glitter powders and other fine particles.

In addition to glitter production, these knives are also used in the creation of decorative paper products, holographic materials, and other fine-cutting applications. The use of glitter cutting machine knives ensures that the glitter pieces are cleanly cut without fraying or losing their sparkle.

5. Machine Used to Cut Moulding Knives

In the construction and home decor industries, machines used to cut moulding knives are vital for producing perfectly shaped and finished decorative moulding. Moulding is often used for crown moulding, baseboards, window trim, and door frames. The knives used in these machines are specifically designed to handle the fine detail and precision required for these intricate shapes.

Moulding knives are typically made from high-carbon steel or carbide to ensure they can handle the demands of continuous cutting. Whether using CNC routers or specialized moulding machines, having the right knives is crucial for producing smooth, flawless cuts that require minimal additional sanding or finishing.

6. Machines Knives to Cut Wallpaper

The wallpaper industry requires a different set of cutting tools, and machines knives to cut wallpaper are essential for achieving accurate, straight cuts on wallpaper rolls. These knives need to be sharp enough to slice through different types of wallpaper materials—whether it’s paper, vinyl, or fabric-backed options—without tearing or damaging the material.

In commercial wallpaper production, cutting machines for wallpaper are often automated for efficiency. The wallpaper cutting knives used in these machines are designed to work quickly and precisely, ensuring that wallpaper is cut to the desired length without any defects. Proper maintenance and sharpening of these knives are critical for avoiding ragged edges that could affect the wallpaper’s aesthetic quality.

7. Paper Cutting Machine Knives

Finally, paper cutting machine knives are perhaps some of the most widely used cutting tools across various industries. From printing presses to packaging production lines, these knives ensure that large sheets of paper are sliced into smaller, more manageable sizes. Whether it’s cutting newspaper, magazines, or cardboard for packaging, paper cutting knives provide the precision necessary for smooth, clean cuts.

The knives used in paper cutting machines are typically made from hardened steel or carbide to maintain sharpness and reduce the frequency of replacements. Regular maintenance, including sharpening and cleaning, helps prevent dullness that could lead to uneven or jagged cuts, which could compromise the quality of the final product.

| Type of Knife | Material | Common Applications |

|---|---|---|

| Dowel Machine Cutting Knives | High-quality steel | Woodworking, furniture making |

| Glitter Cutting Knives | Stainless steel | Crafting, decorative applications |

| Wallpaper Cutting Knives | High-carbon steel | Wallpaper cutting, home decor |

| Paper Cutting Knives | Carbide or steel | Printing, packaging, paper cutting |

Conclusion

Cutting machine knives are indispensable in numerous industries, playing a vital role in ensuring precision, consistency, and efficiency. Whether you're working with textiles, wood, paper, or glitter, there is a specialized cutting machine knife designed to meet your needs. From cloth cutting knives for Eastman machines to CNC 4 knives V-groove cut machines, dowel machine cutting knives, and glitter cutting machine knives, these tools are engineered to provide high-quality results.

Maintaining high-quality knives, such as machines knives to cut wallpaper or paper cutting machine knives, not only improves production efficiency but also reduces downtime and minimizes defects in the final product. By investing in the right knives and ensuring their upkeep, businesses can boost productivity, enhance product quality, and remain competitive in their respective markets.

As you explore cutting machine knives for your operations, be sure to choose the best materials and designs that fit your specific application to achieve the best results possible.