Providing high-precision and high-quality blades

MISIQI Machinery Technology

Get to know MISIQI faster

Company Profile

-

Customized

Dozens of product types and thousands of specifications. We support customized sizes, materials and geometries to match your machines and applications.

-

20+ Years

With more than 20 years of blade manufacturing experience, we understand real production conditions and help customers choose suitable, cost-effective solutions.

-

Process

More than 20 processing technologies, combined with strict process control and inspection, ensure stable product quality and reliable cutting performance.

High Precision from MISIQI

We focus on providing customers with suitable blade solutions, not just products. According to your actual production needs, we offer professional purchasing advice and deliver high-precision, high-quality blades that help improve efficiency and reduce downtime.

Company Business Scope

How We Work with You

-

Tailored to Customer Requirements

We design and manufacture blades according to your specific needs. By optimizing heat treatment, geometry, material and cutting angles, we ensure each blade is precisely matched to your machine, material and cutting conditions.

-

Sketch

You can simply provide a sketch with the required shape and key dimensions. Our engineers will communicate with you in detail, complete the technical parameters and turn your idea into a feasible blade design.

-

Specimen Reproduction

We can reproduce blades based on your samples. By analyzing material composition and hardness, we accurately copy the original blade or optimize it to improve service life and cutting performance.

-

Drawing

If you already have technical drawings, we can manufacture strictly according to your specifications. Tolerances can follow industry standards or your own customized tolerance requirements.

-

Problem Analysis & Output Optimization

At our factory or at your site, we work with your team to analyze cutting problems and optimize output. This may include adjusting materials, angles, blade shapes, coatings or polishing processes to improve cutting efficiency, extend blade life and reduce overall cost.

-

Competitive Pricing

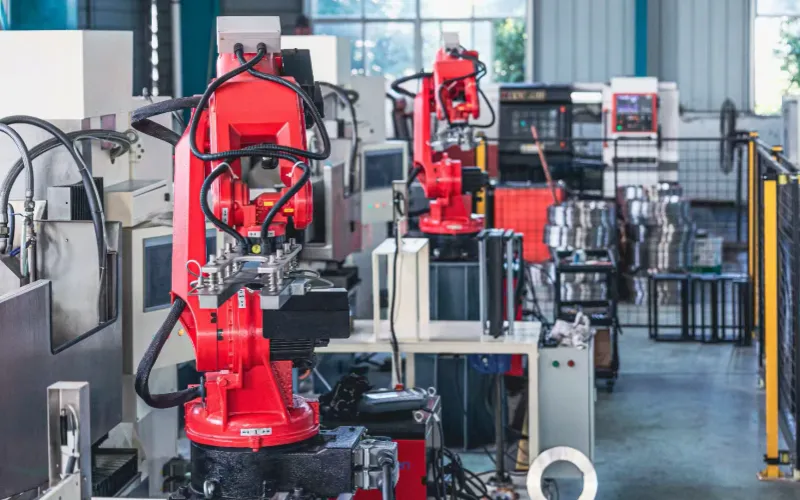

With more than 10 precision production lines and efficient batch manufacturing, we are able to offer competitive prices while maintaining strict quality standards, giving you a strong cost advantage in your market.

Enterprise Advantage Display

Why Customers Choose MISIQI

-

Quality and Consistency

ISO 9001:2015, ISO 13485:2016 certified

Automatic in-process measurement of key parameters

Optional batch tracking: each blade can be laser-marked with a unique serial number for full traceability -

Expertise and Experience

In-house tool & die shop and metallurgy laboratory

CAD-based development and rapid prototyping capabilities

Cooperation with leading users and research institutes

Nearly 20+ years of focused experience in industrial blades -

Your Productivity and Efficiency

Increased blade durability and reduced retooling times

Measurably higher machine uptime and less unplanned stops

Excellent cutting quality, reducing rework and inspection

Higher yield per cut, helping you lower cost per product

Company Environment & Facilities

Providing high-precision and high-quality blades

Why Choose MISIQI

-

Abundant Production Experience

Nearly 20 years of focus on industrial blades, helping you select the most suitable products for your machines and materials.

-

Professional Technical Team

Our engineers provide technical support on material, hardness and geometry. Advanced heat treatment technology ensures stable, repeatable blade quality.

-

Experienced and Responsible Workers

Skilled operators follow strict work instructions and inspection standards, putting real care into every blade we produce.

-

High-Accuracy Equipment

Precision grinding and measuring equipment keep thickness tolerances within ±0.002 mm, ensuring high accuracy and consistent cutting results.

Find quick answers to common questions

FAQ – Quick Answers for Buyers

-

01

Frequently Asked Questions (FAQs)

We offer a wide range of products, including food processing knives, industrial cutting tools, and specialized blades for various applications. Our product line includes knives for bakery and pastry, meat processing, fruit and vegetable processing, as well as blades for ceramics, printing machinery, and papermaking.

-

02

What materials are your products made from?

Our products are made from high-quality materials such as:

Stainless Steel: Rust-resistant and food-safe, ideal for food processing and industrial applications.

Ceramic: Lightweight and extremely sharp, suitable for precision cutting.

High-Carbon Steel: Offers excellent edge retention but requires more maintenance, ideal for professional use. -

03

Can I customize the dimensions and design of the products?

Yes, we offer customization options for blade length, width, thickness, and edge profiles. You can also choose the handle material and design to suit your specific needs. Simply provide us with your specifications or a sketch, and we will tailor the products to your requirements.

-

04

How do you ensure the quality of your products?

We adhere to strict quality control standards, including ISO 9001:2015 and ISO 13485:2016 certifications. We use automatic in-process measurement for key parameters and batch tracking to ensure consistency and traceability. Each product undergoes rigorous testing to meet high performance and safety standards.

-

05

Are your products suitable for industrial use?

Absolutely. Our products are designed for various industrial applications, including food processing, ceramics, printing machinery, and papermaking. They are built to withstand heavy use and maintain their performance over time.

-

06

What is the lead time for custom orders?

The lead time for custom orders depends on the complexity and quantity of the order. Typically, it ranges from 2 to 4 weeks. We will provide you with a specific timeline once we receive your detailed specifications and approve the prototype.

-

07

Do you offer any warranties or guarantees?

Yes, we offer a warranty on our products to ensure customer satisfaction. The warranty covers defects in materials and workmanship for a specified period, typically 12 months. If you encounter any issues, please contact our customer service team for assistance.

-

08

How should I maintain my products?

To ensure the longevity and performance of your products, follow these maintenance tips:

Clean the products thoroughly after each use to prevent residue buildup.

Store the products in a dry place to avoid rust.

Sharpen the blades regularly using a suitable honing tool.

Avoid dropping or mishandling the products to prevent damage. -

09

Can you provide samples for testing?

Yes, we can provide samples for testing upon request. Please contact our sales team to discuss your requirements and arrange for sample delivery.

-

10

What is the minimum order quantity (MOQ)?

The minimum order quantity varies depending on the type of product and customization level. For standard products, the MOQ is typically 100 units, while for custom products, it may be higher. We can discuss the specific MOQ with you during the consultation process.

-

11

Do you offer international shipping?

Yes, we offer international shipping to ensure our products reach customers worldwide. Shipping costs and delivery times will vary based on your location. Contact us for a shipping quote and estimated delivery time.

If you have any further questions or need more information, please feel free to contact our customer service team. We are here to help!