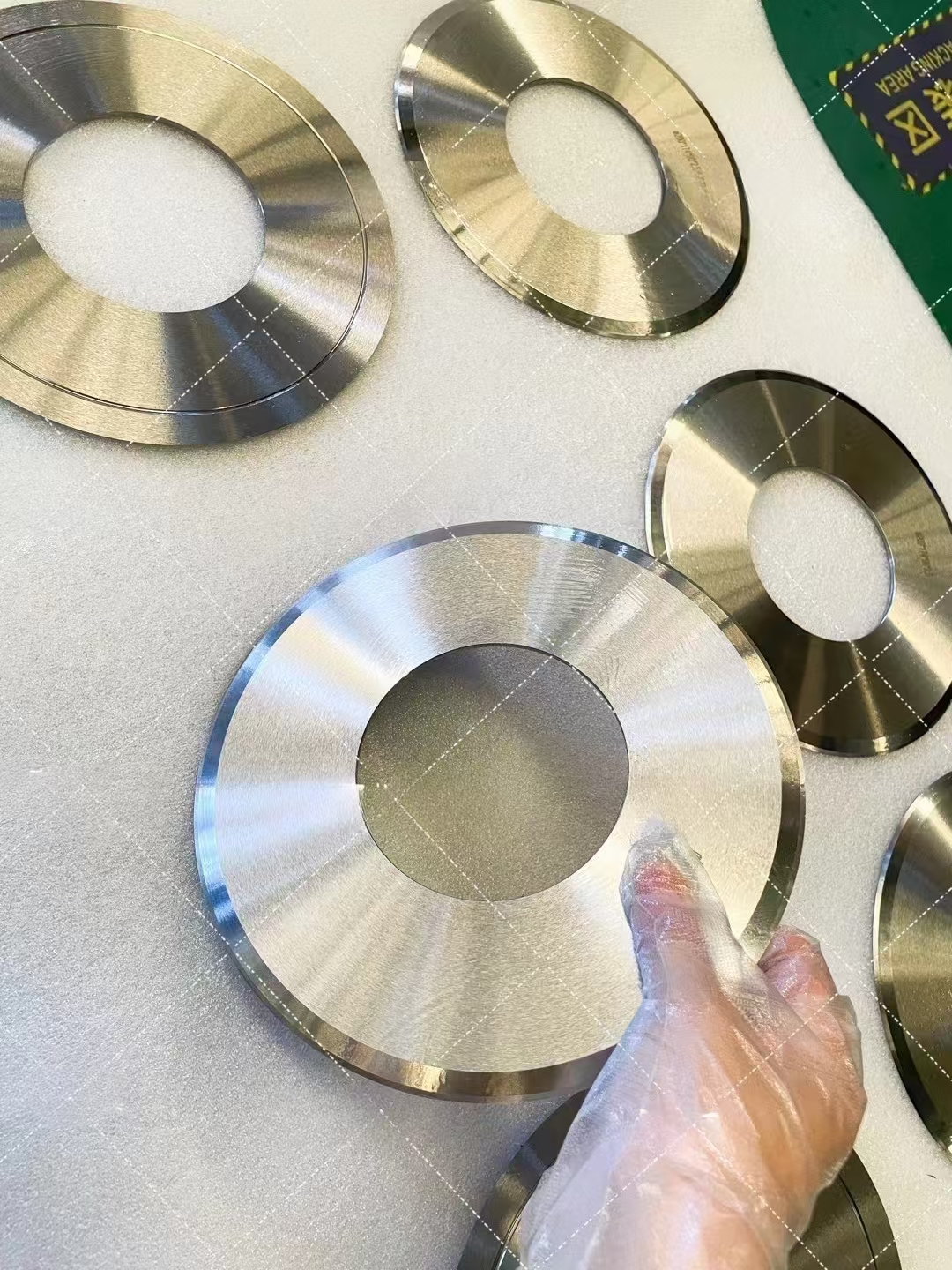

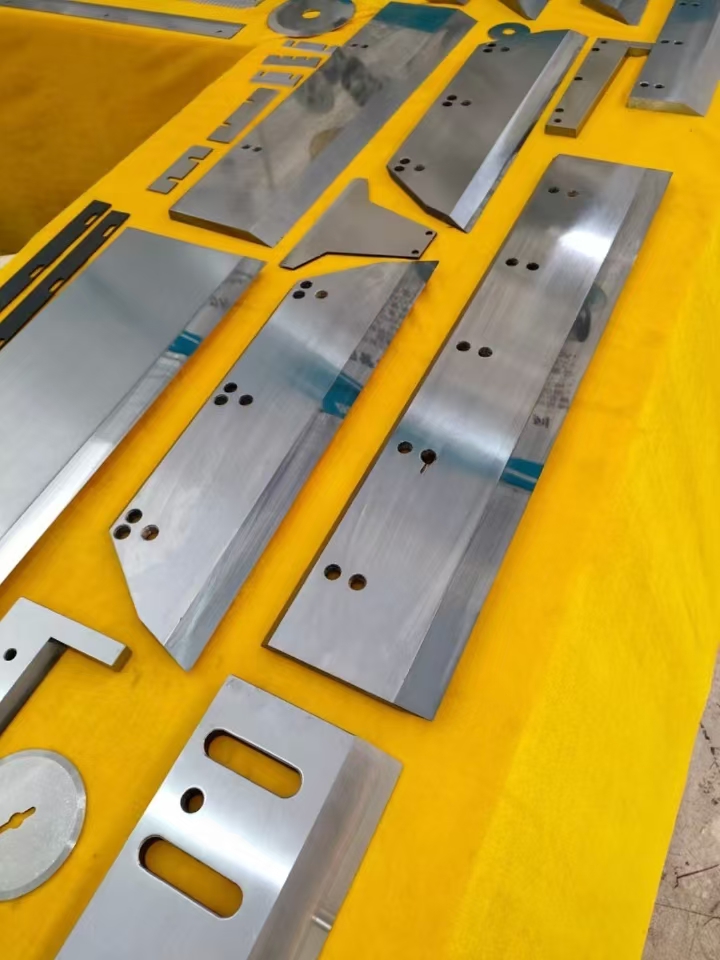

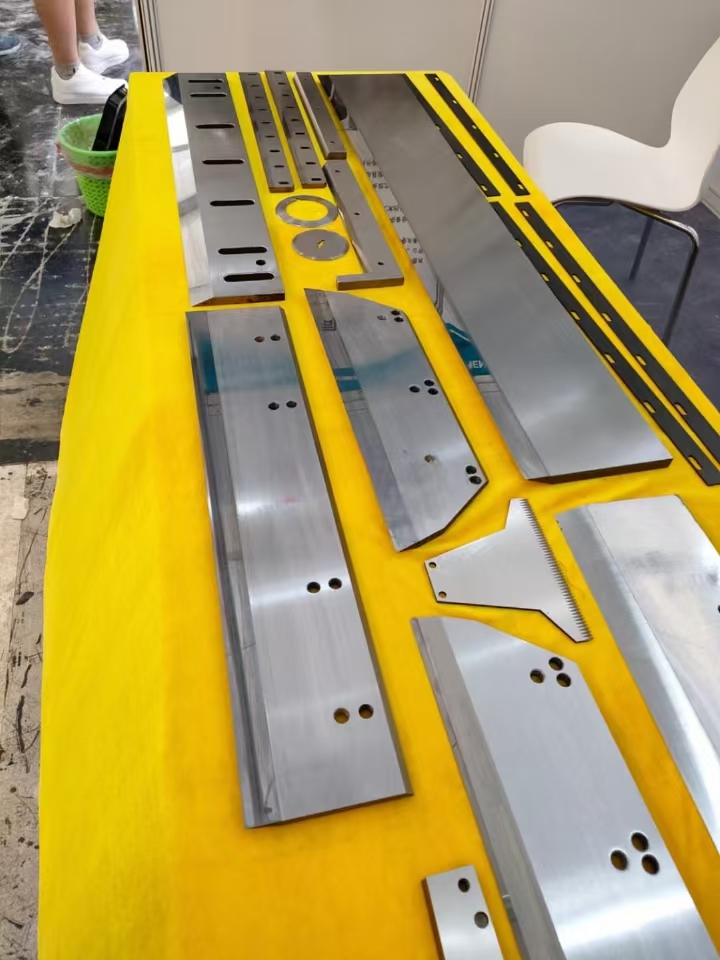

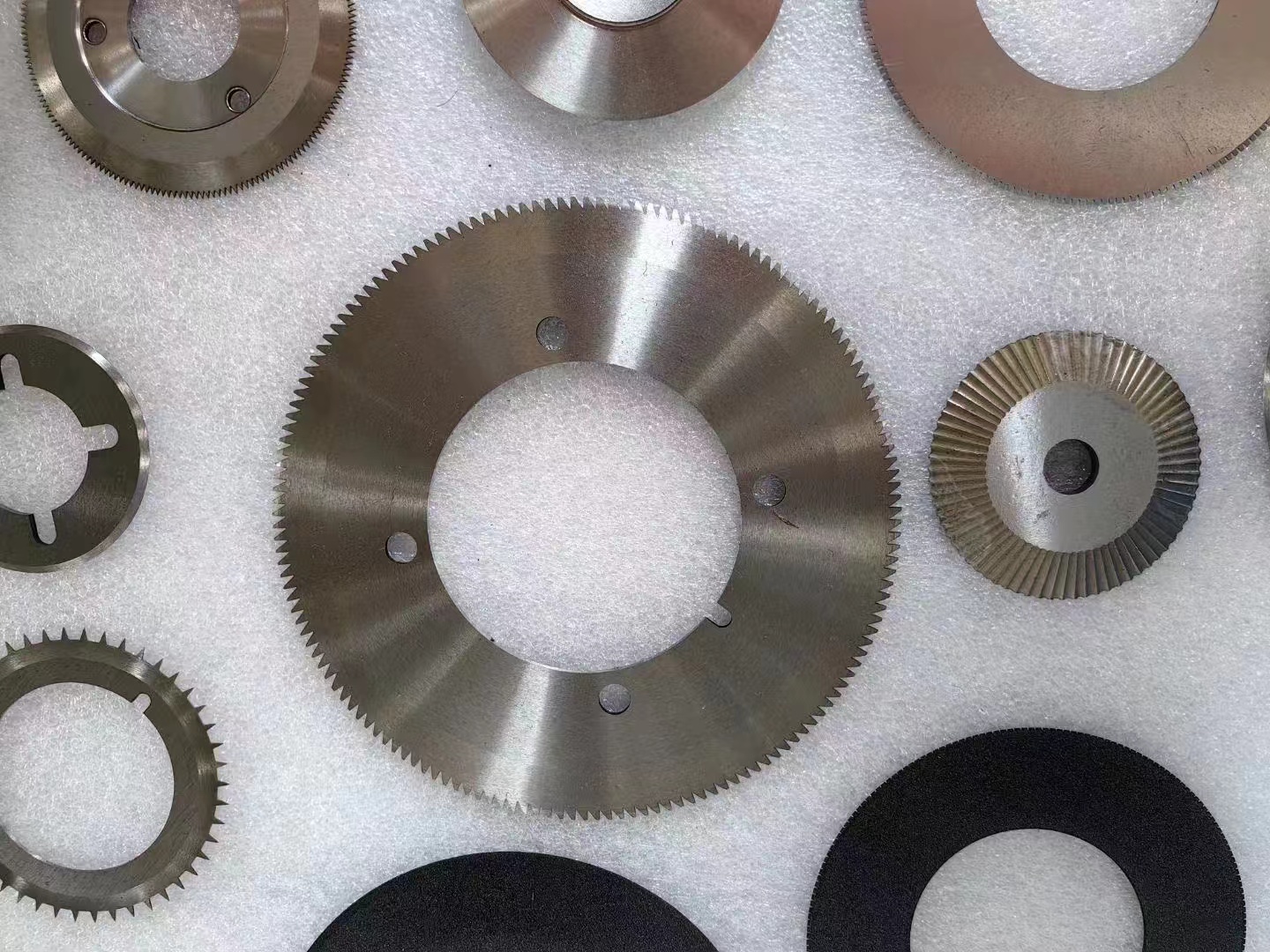

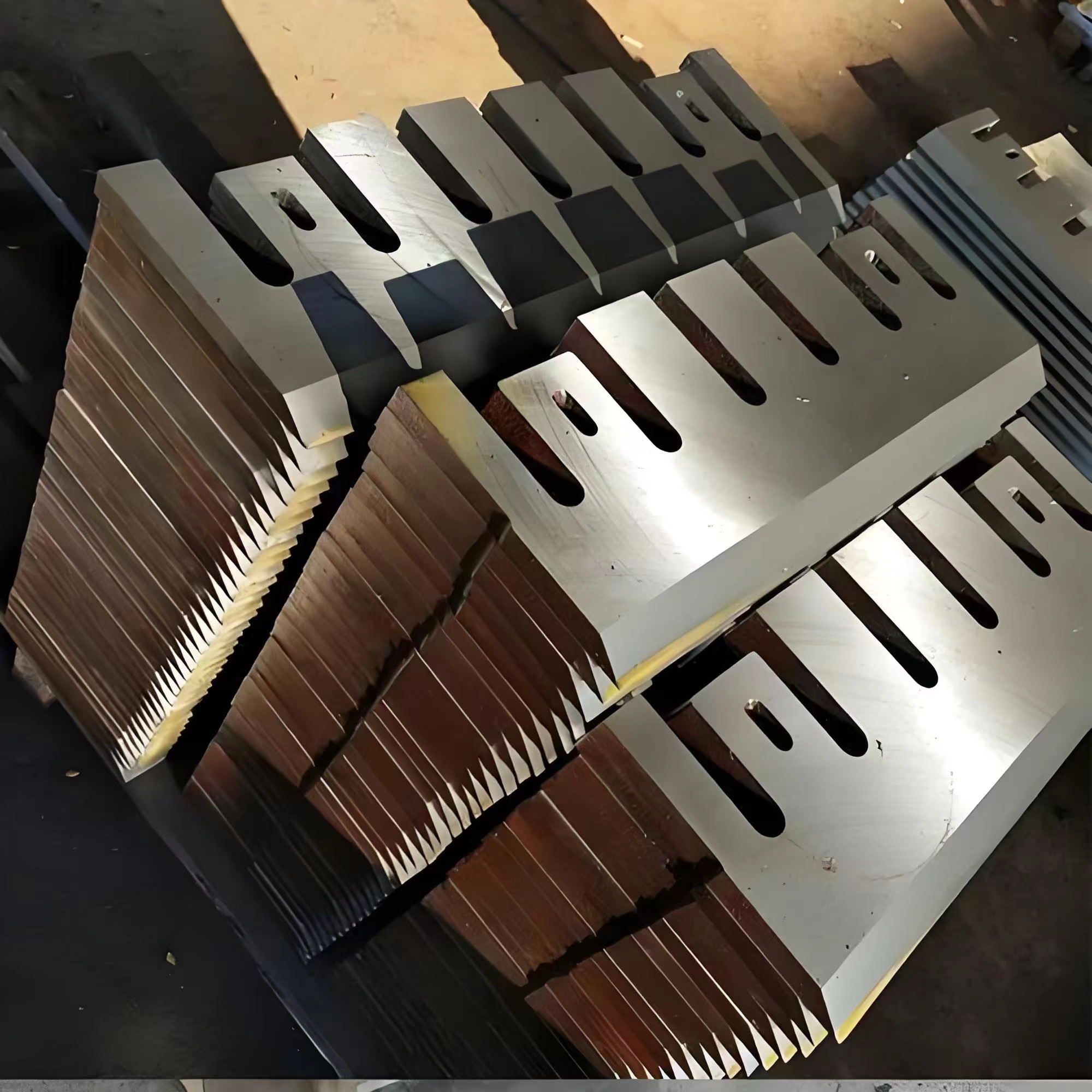

Our Industrial Blades are designed for use in paper rewinding machines and carton packaging industries. Featuring both circular blades for slitting and straight blades for shearing, these tools ensure precise and efficient cutting operations. Circular blades are ideal for slitting paper rolls and corrugated sheets, while straight blades are perfect for shearing corrugated boards and creating clean edges for carton assembly. Packaged in sturdy wooden boxes with protective plastic film, our blades are delivered ready for use, ensuring optimal performance and reliability.

To ensure the highest quality and performance in our Industrial Blades, we select materials based on their durability, sharpness retention, and compatibility with the materials being cut. Below are the key materials used for our blades:

Circular Blades

-

High-Speed Steel (HSS):

- Features: High heat resistance and good wear resistance.

- Application: Ideal for continuous operation and high-speed cutting in paper rewinding and corrugated board production.

-

Tungsten Carbide:

- Features: Extremely hard and retains sharpness well under heavy use.

- Application: Best suited for cutting abrasive materials and for applications requiring long-lasting sharpness, such as corrugated board slitting.

-

Stainless Steel:

- Features: Corrosion-resistant and maintains edge sharpness.

- Application: Suitable for clean cuts in softer materials like paper and light-duty packaging materials.

Straight Blades

-

High-Carbon Steel:

- Features: Good balance between hardness and toughness.

- Application: Suitable for general-purpose cutting where moderate wear resistance is sufficient, such as shearing corrugated boards.

-

Tool Steel:

- Features: High wear resistance and toughness.

- Application: Ideal for applications requiring a strong, durable edge, particularly in heavy-duty cutting operations.

-

Ceramic:

- Features: Extremely hard and holds an edge well but is more brittle.

- Application: Used in applications where minimal material deformation is critical, despite the risk of breakage under impact.

Coatings

To enhance the performance and lifespan of the blades, we offer several coating options:

-

Titanium Nitride (TiN):

- Benefits: Reduces friction and increases wear resistance.

- Application: Suitable for all types of cutting operations to improve blade life.

-

Diamond-Like Carbon (DLC):

- Benefits: Provides a low-friction surface and enhances hardness.

- Application: Recommended for cutting abrasive materials to reduce wear.

-

Chrome Plating:

- Benefits: Offers corrosion resistance and improves surface finish.

- Application: Beneficial for environments with high humidity or corrosive substances.

Each material selection is made based on the intended application, the type of material being cut, and the operating conditions of the machinery. Our engineering team can help determine the best combination of materials and coatings to optimize tool performance for your specific requirements.