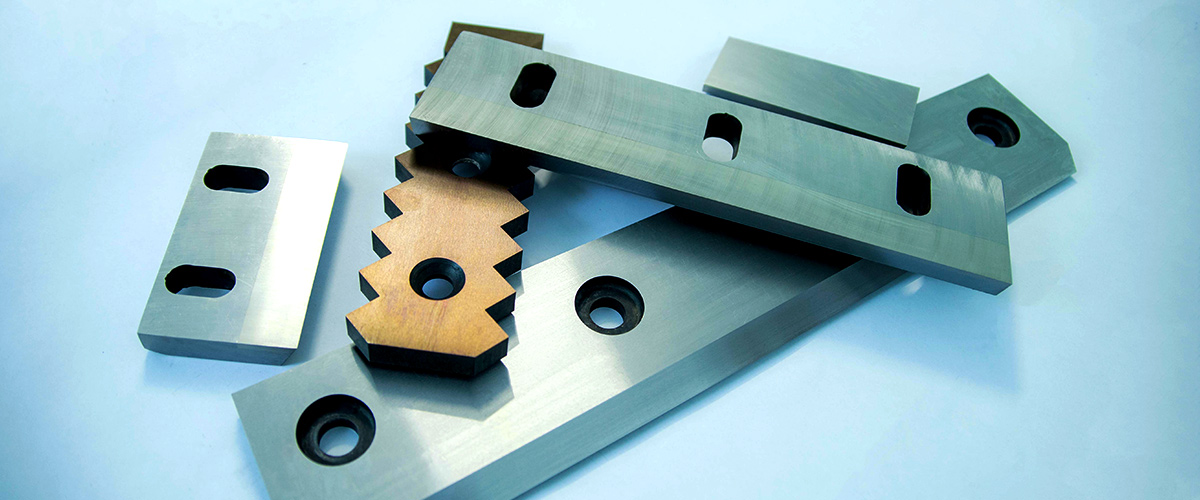

Knives for Processing Polymers, Plastics, and Plastic Materials

Misiqi quickly and efficiently manufactures all types of knives for crushers, shredder knives, agglomerators, guillotines, strand cutters, and more.

A modern and effective solution is the production of knives with welded plates made of D2 steel (USA). For the first order of knives using this technology, there is a 10% discount.

Our advantage is the fastest production time: 10 working days from the moment the drawings are approved for a standard set of knives!

We will gladly manufacture knives for crushers, shredders, agglomerators, and guillotines of various configurations from steels such as Х12МФ, 6ХВ2С, 9ХС, with welded plates from BOHLER K110 steel, which are in no way inferior in quality to knives made from expensive alloyed steel Х12МФ, and at the same time have an attractive price, as well as knives with plasma-sprayed silicon carbide.

To manufacture components, it is not necessary to have a drawing! You can make a sketch or entrust everything to our design bureau, where specialists will take all the necessary measurements and prepare a drawing of the product for you.

Most companies manufacture knives only based on provided design documentation. However, often the documentation is missing, and there is no possibility to create a new one. Our company provides a service for preparing design documentation based on sketches and samples from the client.

The welded plates of the knives are made from BOHLER K110 steel. This steel is dimensionally stable, high-carbon, high-chromium (12%). It is particularly suitable for air hardening and has high toughness. The base of the knives is made from high-quality structural carbon steel, which provides the necessary elasticity and strength to withstand extreme loads during crushing.

Surfacing is intended for the manufacture of bimetallic (two-layer) products. The base is made of 40Х steel – a high-quality structural carbon steel that ensures the necessary strength of the product. The surfacing is applied to the working surface of the knife by high-tech application of silicon carbide particles at high temperatures. The plasma surfacing method has unique properties inherent only to this method of knife production – it not only restores the active metal surface from oxide films on the deposited particles but also cleans the substrate surface from oxides. Thus, the knife product acquires enhanced characteristics: wear resistance, impact strength, resistance to abrasive wear, and an increased interval before re-sharpening.

Guillotine knives are tools that directly perform the function of cutting plastics.

Knives are used in various equipment for grinding polymeric materials. The grinding process itself requires significant energy expenditure and is characterized by the release of a large amount of heat and rapid wear of the cutting edges, which are in constant contact with the processed material. The quality of the crushers' work largely depends on the degree of contamination and the type of materials used in the production of knives.

Shredder knives are designed for primary shredding of large waste. The knives mainly have a square cross-section, used primarily in single-rotor shredders. For multi-rotor shredders, disk-type knives are used.

Agglomerator knives are used to chop plastic bottles, process waste from films, polymer packages with thin walls, and to grind, dry polyethylene, polypropylene, and polystyrene film waste, grind PET bottles, and other polymer products with thin walls.

The Main Advantage of Misiqi's Plastic Knives is the Heat Treatment in a Vacuum Furnace

- Virtually zero oxidation and no decarburization of the processed products

- Minimal distortion during hardening (both in oil and gas)

- Suitable for both small and large workpieces

- Reduced time for thermal and chemical-thermal treatment

- Quick change of processing mode

- Cold furnace walls

- Reduced energy costs due to push-button operation

- Simulation of normalization and annealing processes for steel

- Ease of repair and accessibility for maintenance

- The highest degree of automation among furnace heating equipment

To place an order or get the necessary information, contact our manager in China online, by email at info@misiqiblades.com, or request a free callback. We respond promptly to all incoming requests. Additionally, our company offers plastic recycling blades and other equipment at affordable prices.