When it comes to paper processing, the role of facas de máquina cannot be overstated. These specialized cutting tools are crucial in ensuring precision, speed, and efficiency during various stages of paper production, from slitting and trimming to guillotining and perforating. If you're involved in the paper industry or operating a paper converting machine, understanding the importance of high-quality machine knives can help optimize performance and reduce downtime.

In this guide, we will explore the different types of machine knives for paper, how to select the best ones for your application, and the essential features to look for when purchasing these knives. We will also discuss the maintenance practices that ensure longevity and optimal performance.

Types of Machine Knives for Paper Processing

The paper industry involves a variety of operations, each requiring specialized knives. Below are some common types of machine knives used in paper processing:

1. Slitter Knives

Slitter knives are used for cutting paper into smaller widths. These knives are essential in operations where paper rolls need to be slit into specific sizes before further processing or packaging.

- Materiais: Slitter knives are typically made from aço rápido (HSS) ou carboneto to withstand the heavy-duty cutting required.

- Características: The knives often have a sharp edge and are designed for high-speed operations, making them ideal for continuous production environments.

Table 1: Slitter Knife Applications

| Aplicativo | Descrição | Best Material |

|---|---|---|

| Roll Slitting | Cutting large paper rolls into specific widths | Carbide, HSS |

| Slitting & Scoring | Cutting and scoring paper for packaging | Carbide, HSS |

| Corrugated Slitting | Cutting thick paper, typically used in corrugated board manufacturing | Carbide, HSS |

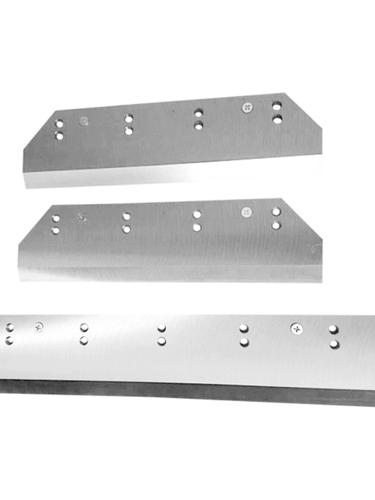

2. Facas de guilhotina

Guillotine knives are used for large-scale cutting operations, typically where paper sheets need to be cut into specific sizes. These knives are often used in finishing departments, such as when trimming large paper sheets into standard sizes.

- Materiais: High-carbon tool steel is commonly used for guillotine knives due to its toughness and sharpness.

- Características: Guillotine knives are heavy-duty and capable of cutting thick sheets with precision. They are designed for high-volume cuts and are often used in sheet-fed paper cutters.

3. Perforating Knives

Perforating knives are essential in paper processing when a specific pattern or perforation needs to be created on paper sheets. These knives are widely used in the production of tickets, coupons, e notebooks where tearable perforations are required.

- Materiais: Carbide-tipped or tool steel perforating knives provide high durability.

- Características: These knives often feature custom patterns and are engineered to provide clean and precise perforations with minimal wear.

4. Trim Knives

Trim knives are used for cutting the edges of paper after it has been printed. These knives are crucial for ensuring that the paper is trimmed to the correct size and free of any excess material.

- Materiais: Tool steel e carboneto are preferred for trim knives due to their ability to maintain a sharp edge and endure repeated cuts.

- Características: Trim knives are designed for precision cuts and can be equipped with multiple blade edges to enhance productivity.

5. Cutter Blades for Paper Converting Machines

Cutter blades are used across various machines for cutting, trimming, and slitting paper in the converting process. These blades must be highly resistant to wear and maintain their sharpness even after extensive use.

- Materiais: High-speed steel (HSS), carboneto, e carboneto de tungstênio are common materials for cutter blades in the paper industry.

- Características: Cutter blades typically have a sharp edge and can be used for high-volume cutting.

6. Paper Knife Sets

Some paper processing systems require sets of knives for different stages of production. These sets include multiple types of blades, such as slitter knives, trim knives, e facas de guilhotina, that work together to streamline the entire paper production or converting process.

How to Choose the Best Machine Knives for Paper Processing

Selecting the best machine knives for your paper processing needs requires careful consideration of several factors, including machine compatibility, material strength, and the specific requirements of your application. Below are key factors to consider when choosing the right knives for paper cutting:

Material of the Knives

The material used to make paper cutting knives has a direct impact on their performance e longevity. The two main materials used in paper knives are aço rápido (HSS) e carboneto.

- Aço rápido (HSS): Known for its ability to retain sharpness and withstand heat, HSS is an excellent choice for knives that need to stay sharp under regular use.

- Carboneto: Carbide-tipped knives offer extra durability and are often used in high-performance cutting tasks, such as cutting thick or dense papers.

Table 2: Material Comparison for Machine Knives

| Material | Vantagens | Melhor para |

|---|---|---|

| Aço rápido (HSS) | Good sharpness retention, resistant to heat | General-purpose slitting & trimming |

| Carboneto | Extremely durable, retains sharpness longer, withstands wear | Cutting thick paper, high-volume applications |

| Aço para ferramentas | Tough and resistant to wear | Heavy-duty cutting, guillotine knives |

Knife Sharpness and Edge Design

The sharpness and edge design of the knife affect how cleanly it cuts through paper. A sharp edge produces a clean cut and reduces the chances of tearing or fraying. The geometry of the edge can also impact cutting efficiency. For example:

- Straight-edge knives provide consistent and precise cuts.

- Serrated-edge knives are better for certain applications where rougher or more aggressive cutting is needed.

Knife Size and Compatibility

Different paper cutting machines require knives of specific sizes and shapes. Ensure the knife you select matches the dimensions and specifications of your equipment. Incorrectly sized knives can lead to subpar cutting results and increased wear on the machine.

Key Benefits of High-Quality Machine Knives for Paper

Investing in high-quality machine knives for paper can significantly improve the efficiency and output of your paper processing operations. Here are the key benefits:

1. Improved Precision

High-quality knives ensure that every cut is precise, reducing waste and improving the overall quality of the finished paper products.

2. Enhanced Durability

Durable materials like carboneto extend the life of your knives, allowing for longer cutting cycles and fewer replacements.

3. Faster Production Speeds

Sharper knives require less force to cut through paper, enabling machines to operate at higher speeds. This results in increased productivity without compromising on cut quality.

4. Tempo de inatividade reduzido

Using the right knives minimizes the frequency of knife replacements and maintenance, leading to less downtime in the production process.

Maintaining Your Machine Knives for Optimal Performance

To get the most out of your paper processing knives, proper maintenance is essential. Here are some tips to ensure your knives remain in top condition:

1. Afiação regular

Frequent sharpening is necessary to maintain sharpness and prevent dull blades from damaging paper or the machine.

2. Armazenamento adequado

Store knives in a dry, clean place to avoid rust and corrosion, which can significantly reduce their performance.

3. Inspeção regular

Inspect your knives for wear and damage regularly. Dull, chipped, or damaged knives should be replaced immediately to avoid further damage to the paper or the machine.

4. Lubrication

Some machines require lubrication of their knives to reduce friction and wear. Be sure to follow the manufacturer's recommendations for maintenance.

Conclusion: Investing in the Right Machine Knives for Paper

In the paper industry, selecting the right machine knives is crucial for enhancing productivity, ensuring precise cuts, and improving the quality of the finished product. Whether you're using slitter knives, facas de guilhotina, ou perforating blades, the choice of material, design, and maintenance practices all play a role in optimizing your machine's performance.

By understanding the different types of machine knives and their specific applications, you can make informed decisions that will lead to higher efficiency, tempo de inatividade reduzido, and ultimately a better end product. Investing in high-quality machine knives for paper processing is an investment in the future of your business.