Industrial knives are essential tools used in various sectors, from food processing to paper production, textiles, and metalworking. These knives are designed to withstand demanding environments and high-volume tasks. However, like any heavy-duty equipment, they require proper maintenance and care to ensure optimal performance, longevity, and safety.

Understanding Industrial Knives

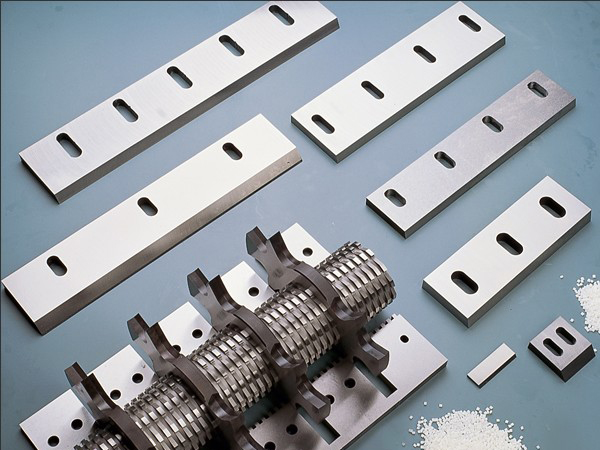

Industrial knives are cutting tools designed for industrial applications where precision, durability, and efficiency are paramount. These knives come in different shapes, sizes, and materials, depending on their specific function. They are commonly used in processes such as slicing, shredding, cutting, or grinding, often in high-speed operations. Due to the heavy-duty nature of these tasks, industrial knives are subject to wear and tear, requiring periodic attention and care.

Limpeza regular

The first step in maintaining an industrial knife is regular cleaning. After every use, knives should be thoroughly cleaned to remove any food particles, chemicals, or contaminants that may have accumulated during the cutting process. This is particularly important in industries like food processing, where hygiene is critical.

To clean the knife, use a soft cloth or brush to wipe down the blade. For tougher residues, mild detergents or specialized cleaners may be required. Avoid using harsh chemicals that could damage the knife's surface or affect its performance. After cleaning, it’s crucial to dry the knife completely to prevent rust formation, especially for knives made of carbon steel or other materials prone to oxidation.

Sharpening and Honing

Industrial knives, like any cutting tool, lose their sharpness over time. Dull blades can lead to inefficiency, increased friction, and poor-quality cuts, which may compromise production quality. Regular sharpening and honing are essential to maintain the cutting performance of industrial knives.

Sharpening removes material from the blade to restore its edge, while honing realigns the existing edge to maintain sharpness between sharpenings. For knives that require frequent sharpening, it’s advisable to have a professional sharpening service or invest in a sharpening machine designed for industrial use. Some knives, especially those made from high-quality stainless steel or tungsten carbide, may need less frequent sharpening, but they should still be checked regularly for sharpness.

Armazenamento adequado

When not in use, industrial knives should be stored properly to prevent damage. Storing knives in a dry, cool environment is essential to avoid corrosion. A knife storage system, such as a dedicated rack or blade box, can help prevent physical damage to the blades. When storing knives with coatings, it’s important to ensure they are not scratched, as this could affect their cutting performance and durability.

Additionally, knives should be stored away from areas where they could be exposed to extreme temperatures or chemicals that could cause degradation. For example, some industrial knives may become brittle when exposed to low temperatures, which could lead to breakage during operation.

Regular Inspections

Regular inspections are vital to identify signs of wear and tear before they become critical issues. Check the knife regularly for any cracks, chips, rust, or other forms of damage. If the blade shows any signs of damage, it should be repaired or replaced promptly to avoid compromising safety or performance. Even slight damage can affect the quality of cuts, which may lead to production inefficiencies or safety hazards.

In addition to inspecting the blade, check the knife’s other components, such as the handle, mounting, and safety features. Ensuring that all parts are in good working condition is crucial for the overall performance of the knife.

Lubrication

Some industrial knives, particularly those used in continuous or automated processes, benefit from lubrication. Regularly applying the right lubricant to the moving parts of the knife can help reduce friction, prevent wear, and protect the blade from rust. Make sure to use the appropriate lubricant recommended by the manufacturer, as some lubricants can cause damage or affect the knife's performance if used incorrectly.

Balancing and Alignment

Knives used in high-speed or automated processes may require periodic balancing and alignment to ensure smooth operation. Unbalanced knives can cause vibrations, which can lead to uneven wear, reduced cutting performance, and potential damage to machinery. Regularly check the alignment and balance of the knives, particularly if they are part of a rotating system, to ensure they are functioning optimally.