When it comes to woodworking, having the right tools can make all the difference in achieving high-quality results. Knives for wood machines are among the most critical components, whether you're working with a planer, jointer, or other woodworking machinery. The efficiency and precision of these tools directly impact the finish, accuracy, and speed of your projects.

In this article, we will explore the best knives for woodworking machines, offering guidance on how to choose the right set for your needs, the benefits of different materials, and the maintenance required to ensure long-lasting performance. Additionally, we will discuss the key features that set high-quality woodworking knives apart from the rest, and how they can enhance your workflow.

Understanding the Role of Knives in Woodworking Machines

Knives are essential to several types of woodworking machinery. Whether you're working with a planer knife, jointer knife, ou moulder knife, these tools are responsible for shaping and finishing wood with precision. The quality of the knife can significantly affect the efficiency of your operation, the quality of the finished wood, and the overall speed of your workflow.

Key Factors to Consider When Choosing Knives for Woodworking Machines

Choosing the right knives for your woodworking machine is not a one-size-fits-all decision. Here are some important factors to consider:

1. Material of the Knives

The material used to make woodworking knives is critical to their performance. Common materials include:

- Aço rápido (HSS): Known for its excellent durability and resistance to heat, HSS is commonly used for general-purpose knives. HSS knives tend to retain their sharpness for longer periods compared to other materials.

- Facas com ponta de carboneto: These knives are coated with carbide, making them much harder than steel. While more expensive, carbide knives can last much longer and handle tougher woods with ease.

- Aço para ferramentas: Often used in high-performance applications, tool steel knives provide a balance of sharpness and durability.

2. Knife Sharpness and Maintenance

Sharp knives ensure cleaner cuts and reduce the likelihood of damaging the wood or the machine itself. A dull knife can cause problems such as burn marks on the wood, rough finishes, and even machine malfunctions. Regular sharpening is essential to maintaining the knife’s performance. Some woodworking machines come with easy-to-sharpen knives, while others require more specialized tools and techniques.

3. Knife Length and Size

The size and length of the knife should match the specifications of your machine. For example, a planer knife will have a different length compared to a router knife ou jointer knife. Make sure to consult your machine’s manual to choose the correct size.

Popular Types of Knives for Woodworking Machines

Planer Knives

Planer knives are used in wood planing machines to smooth rough wood surfaces. These knives must be sharp and able to handle both softwoods and hardwoods. Planer knives typically have a straight edge but may also come in spiral configurations for improved cutting efficiency.

Jointer Knives

Jointer knives are used for jointing edges to ensure that pieces of wood fit together perfectly. These knives are designed for precise edge cutting and must remain extremely sharp to avoid damaging the wood.

Moulder Knives

Moulder knives are designed to create decorative profiles in wood. These knives can be highly specialized and are available in a wide variety of shapes, including straight, ogee, or bead profiles. Moulder knives are typically made of high-grade materials to ensure clean cuts and long-lasting durability.

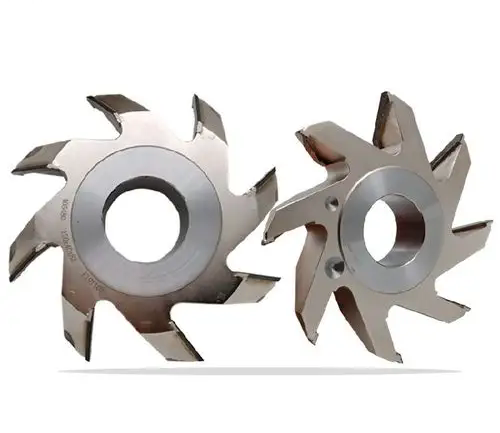

Shaper Knives

Shaper knives are commonly used with shaping machines to cut complex profiles, grooves, and joints in wood. Like moulder knives, these can be custom-shaped to meet specific design needs and come in various sizes.

Key Features of High-Quality Woodworking Knives

Here are some of the essential features that high-quality knives for wood machines should offer:

| Recurso | Descrição |

|---|---|

| Durabilidade | High-quality knives are made from materials like carboneto ou HSS, which can last longer and resist wear. |

| Precisão | A precise edge ensures cleaner, smoother cuts with minimal waste or sanding. |

| Nitidez | The sharper the knife, the cleaner the cut, resulting in less tear-out and smoother finishes. |

| Ease of Maintenance | Knives that are easy to sharpen and maintain will save time and reduce downtime. |

| Versatilidade | A versatile knife can handle a variety of wood types and machining tasks with ease. |

Material Considerations

- Carboneto: Although more expensive, carbide knives are incredibly durable and resistant to wear. They can handle harder materials and extended use without losing sharpness.

- Aço rápido: Often chosen for general-purpose use, HSS knives offer a good balance between performance and cost-effectiveness. They are particularly effective for softwood but may wear faster when used on hardwoods.

- Aço para ferramentas: Tool steel knives are used in specialized applications where extreme durability is required. These knives are often found in professional-grade machinery and are known for their ability to stay sharp even after heavy use.

Maintenance Tips for Long-Lasting Woodworking Knives

Proper maintenance ensures that knives for woodworking machines continue to perform optimally throughout their lifespan. Below are some essential tips:

1. Afiação regular

Regular sharpening prevents dull knives from causing damage to the wood or machine. Depending on the material of the knife, sharpening might involve using specialized tools or taking the knives to a professional.

2. Armazenamento adequado

Store knives in a dry, clean environment to avoid rusting or corrosion. Keep them in a safe place where they won’t be damaged or knocked around.

3. Cleanliness

After use, clean knives thoroughly to remove any wood dust, sap, or resin build-up. This prevents contamination that could affect performance.

4. Avoiding Overheating

Excessive heat can cause knives to lose their sharpness or even warp. Ensure that your machinery operates within the recommended temperature ranges and avoid running the knives for extended periods without sufficient cooling.

Factors Affecting the Performance of Knives for Woodworking Machines

Several factors can influence how well your woodworking knives perform:

- Wood Hardness: Hardwoods require more durable knives, such as those made from carbide, whereas softwoods may be easier to cut with HSS knives.

- Machine Speed: Faster machines require sharper, more durable knives to keep up with the pace and avoid wear and tear.

- Type of Cut: Different cuts, such as jointing, planing, or moulding, require specific types of knives with particular characteristics, such as edge shape and cutting angles.

Selecting the Best Knives for Your Woodworking Projects

Choosing the right set of knives depends on several factors, including the type of machine you're using and the specific demands of your project. If you're working with softwood, you might prefer HSS knives for their cost-effectiveness. However, if you're cutting hardwood or require high precision, facas com ponta de carboneto might be the best option.

Top Picks for Woodworking Knives

| Product | Material | Best for | Price Range |

|---|---|---|---|

| CMT Planer Knives | Carbide-Tipped | General-purpose planing | $$$ |

| Freud Moulder Knives | Aço rápido | Moulding and shaping | $$ |

| Wadkin Jointer Knives | Aço para ferramentas | Edge jointing for hardwoods | $$$ |

| SawStop Shaper Knives | Carboneto | Precision shaping and profiling | $$$$ |

Conclusion: Elevating Your Woodworking with the Right Knives

Selecting the right knives for woodworking machines is crucial for optimizing both the quality of your results and the longevity of your tools. Whether you're shaping intricate profiles with moulder knives or smoothing surfaces with facas de plaina, the material and design of the knives you use will have a significant impact on your work.

By considering the factors outlined in this article, such as material, maintenance, and machine compatibility, you can choose knives that will not only last but also elevate your woodworking projects to the next level. Remember, investing in high-quality knives will save you time, effort, and money in the long run, making them an essential part of any woodworker's toolkit.