How to Choose the Right Food Packaging Machine Knives to Boost Production Efficiency

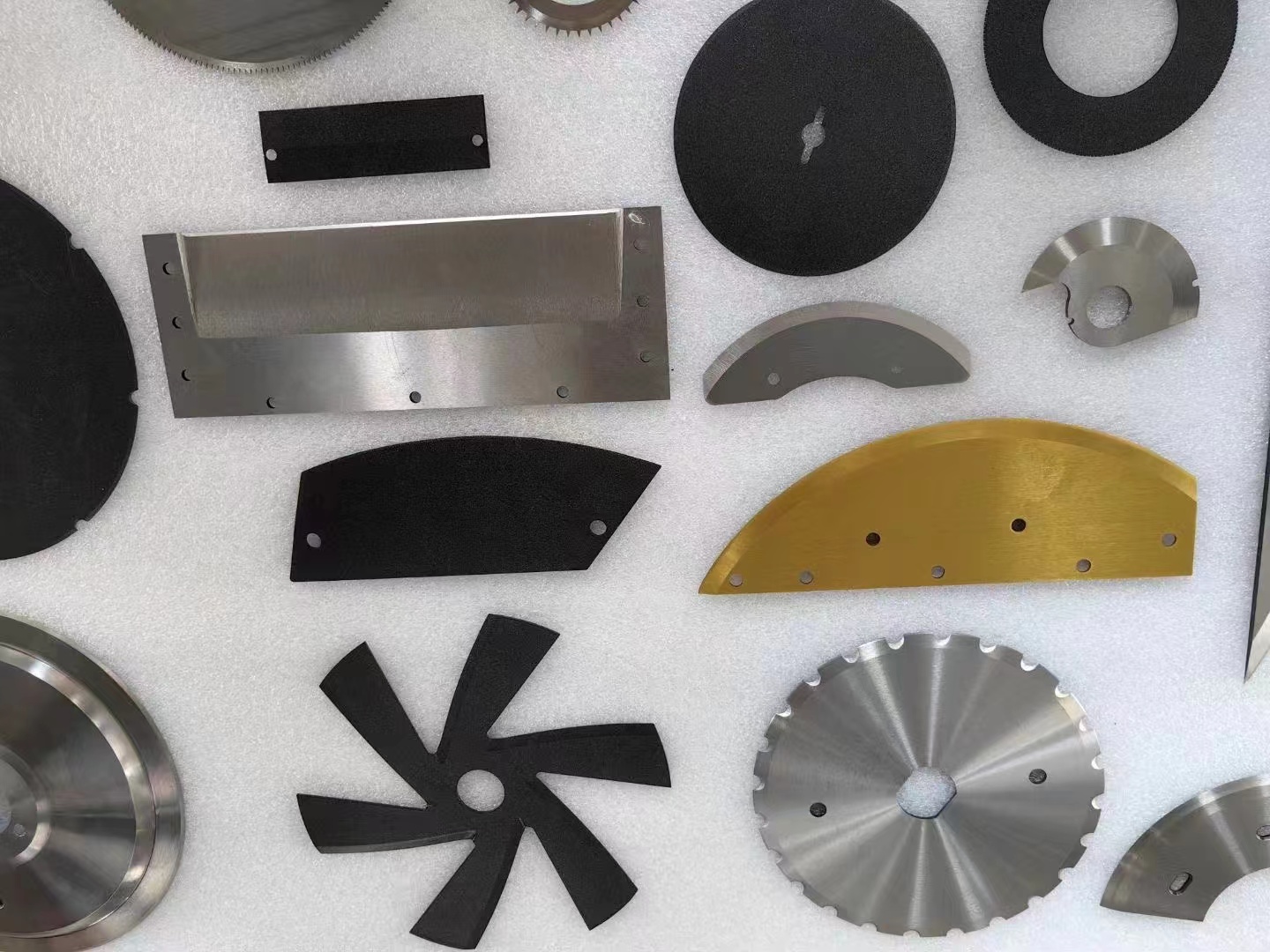

In the food packaging industry, every second counts. Whether you’re sealing pouches, slicing films, or cutting trays, the efficiency of your production line hinges on the tools you use. Food packaging machine knives are at the core of this process, determining not just speed but also the quality and consistency of every package. Choosing the right knives can reduce downtime, improve output, and keep your operation competitive. At Misiqi Blades, we’ve worked with countless manufacturers to refine their cutting solutions. This guide walks you through the key factors—materials, design, compatibility, and maintenance—to help you make informed decisions and elevate your production.

Tabla de contenido

- Why Food Packaging Machine Knives Matter

- Understanding Knife Materials

- Matching Knives to Your Equipment

- The Role of Blade Design

- Maintenance Tips for Longevity

- Real-World Examples: Efficiency in Action

- Conclusion: Optimize with Misiqi Blades

Why Food Packaging Machine Knives Matter

Imagine a production line where every cut is perfect—clean edges, no jams, and no wasted materials. Now picture the opposite: dull blades causing tears, frequent stops, and frustrated operators. The difference lies in your choice of food packaging machine knives. These tools aren’t just accessories; they’re the heartbeat of systems like form-fill-seal (FFS) machines, tray sealers, and flow wrappers. A 2023 report from Packaging Digest noted that optimized cutting tools can boost line efficiency by up to 20%, a game-changer for manufacturers facing tight margins.

At Misiqi Blades, we’ve seen this firsthand. A poorly chosen knife can bottleneck your entire operation, while the right one keeps everything flowing smoothly. This article breaks down how to select knives that align with your goals, drawing from industry insights and practical experience.

Understanding Knife Materials

The material of your food packaging machine knives is the foundation of their performance. Different materials suit different needs, balancing durability, safety, and cost. Here’s a detailed look at your options:

Stainless Steel: The Food-Safe Standard

Stainless steel is the go-to choice for food packaging. It resists corrosion, meets strict hygiene standards (like FDA and EU regulations), and handles wet or sticky products like cheese or meat with ease. Its versatility makes it ideal for cutting films, sealing pouches, or slicing tray lids. However, it may wear faster under heavy use compared to other materials.

High-Speed Steel (HSS): Tough and Affordable

For tougher tasks—like cutting multilayer films or thicker plastics—high-speed steel (HSS) shines. It retains sharpness at high temperatures, making it a cost-effective option for high-speed lines. While not as corrosion-resistant as stainless steel, it’s a solid pick for dry or less demanding applications.

Carbide: The Heavy-Duty Champion

When durability is paramount, carbide steps up. These knives excel in high-wear scenarios, such as continuous cutting of abrasive materials. They last longer than stainless steel or HSS, but their higher cost means they’re best for operations where longevity outweighs initial investment.

| Material | Best Use | Ventajas | Drawbacks |

|---|---|---|---|

| Acero inoxidable | Food films, wet products | Hygienic, corrosion-resistant | Faster wear under heavy loads |

| HSS | Multilayer films, dry cuts | Resistente al calor, asequible. | Less corrosion resistance |

| Carburo | High-wear, continuous use | Larga vida útil, alta dureza. | Higher upfront cost |

Choosing Wisely: Match the material to your product. For wet foods, stainless steel is non-negotiable. For high-speed film cutting, HSS offers value. For relentless production, carbide pays off. Misiqi Blades offers all three, tailored to your specific needs—explore our range here.

Matching Knives to Your Equipment

A knife is only as good as its fit with your machine. Food packaging systems—like FFS machines, vertical baggers, or tray sealers—have unique requirements. A mismatched blade can cause jams, uneven cuts, or premature wear. Here’s how to ensure compatibility:

Know Your Machine Specs

Start with your equipment manual. Check blade dimensions (length, width, thickness), mounting style (e.g., bolted or clamped), and cutting speed. For example, an FFS machine running at 100 cycles per minute needs a knife that can handle that pace without flexing or dulling.

Consider the Material Being Cut

The product you’re packaging dictates the knife’s fit. Thin polyethylene films need sharp, lightweight blades, while thicker laminates demand sturdier options. Wet products like sauces require corrosion-resistant knives, while dry snacks might not.

Work with a Manufacturer

Off-the-shelf knives rarely match perfectly. Custom solutions, like those from Misiqi, align with your machine’s quirks. We’ve helped clients retrofit knives for older FFS models, cutting downtime by 15% simply by adjusting blade angles and fit.

The Role of Blade Design

Beyond material and fit, the design of your food packaging machine knives shapes their effectiveness. Blade shape, edge type, and thickness all play a role.

Blade Shapes

- Straight Edges: Best for clean, linear cuts on films or trays.

- Serrated Edges: Ideal for textured or multilayer materials, reducing slippage.

- Cuchillas curvas: Suited for sealing and cutting in one motion, common in FFS setups.

Edge Sharpness and Angles

A sharper edge cuts faster but dulls quicker. A steeper angle (e.g., 30°) lasts longer but requires more force. For high-speed lines, a balanced 20°-25° angle often works best, a design tweak we’ve perfected at Misiqi.

Thickness and Weight

Thicker blades handle heavy-duty tasks but add stress to the machine. Lighter blades suit delicate cuts but may flex under pressure. Finding the sweet spot depends on your production goals—something our team at Cuchillas Misiqi can fine-tune.

Maintenance Tips for Longevity

Even the best knives falter without care. Proper maintenance extends their life and keeps your line humming.

Afilado regular

Dull blades slow production and tear materials. Sharpen weekly for high-volume runs, or monthly for lighter use. Use a professional service or invest in a compatible sharpening system to maintain edge consistency.

Cleaning for Safety

Food residue builds up fast, risking contamination and corrosion. Clean knives daily with food-safe solutions (e.g., mild detergents), especially for stainless steel. Dry thoroughly to prevent rust.

Inspection Routines

Check for nicks, cracks, or warping weekly. A small flaw can escalate into a full breakdown. Replace blades proactively—waiting for failure costs more in downtime than the blade itself.

Misiqi’s knives are built for easy upkeep, with materials that withstand rigorous cleaning. Pair this with a solid maintenance plan, and you’ll see fewer interruptions.

Real-World Examples: Efficiency in Action

Let’s see these principles at work:

Example 1: Snack Packaging Line

A mid-sized snack producer struggled with inconsistent cuts on their FFS machine, leading to 10% material waste. After switching to Misiqi’s custom stainless steel knives—designed for their specific film thickness—waste dropped to 2%, and output rose by 18%. The key? Perfect material and design alignment.

Example 2: Frozen Food Tray Sealer

A frozen food plant faced frequent blade replacements on their tray sealer, costing $5,000 monthly in downtime. We supplied carbide knives tailored to their high-wear needs, cutting replacements to once every six months and saving $50,000 annually.

These stories show what’s possible when you choose the right tools. Ready to see similar results? Reach out to Misiqi for a consultation.

Conclusion: Optimize with Misiqi Blades

Choosing the right food packaging machine knives isn’t just about buying a blade—it’s about investing in your production’s future. From selecting the perfect material to tailoring designs and maintaining performance, every step counts. At Misiqi Blades, we bring decades of expertise to craft solutions that fit your machines, materials, and goals. Whether you’re sealing snacks or slicing frozen trays, we’ve got you covered.

Want to boost your line’s efficiency? Contact Misiqi Blades today for a free quote on custom knives built for your needs. Let’s cut through the competition together!