Navegación rápida

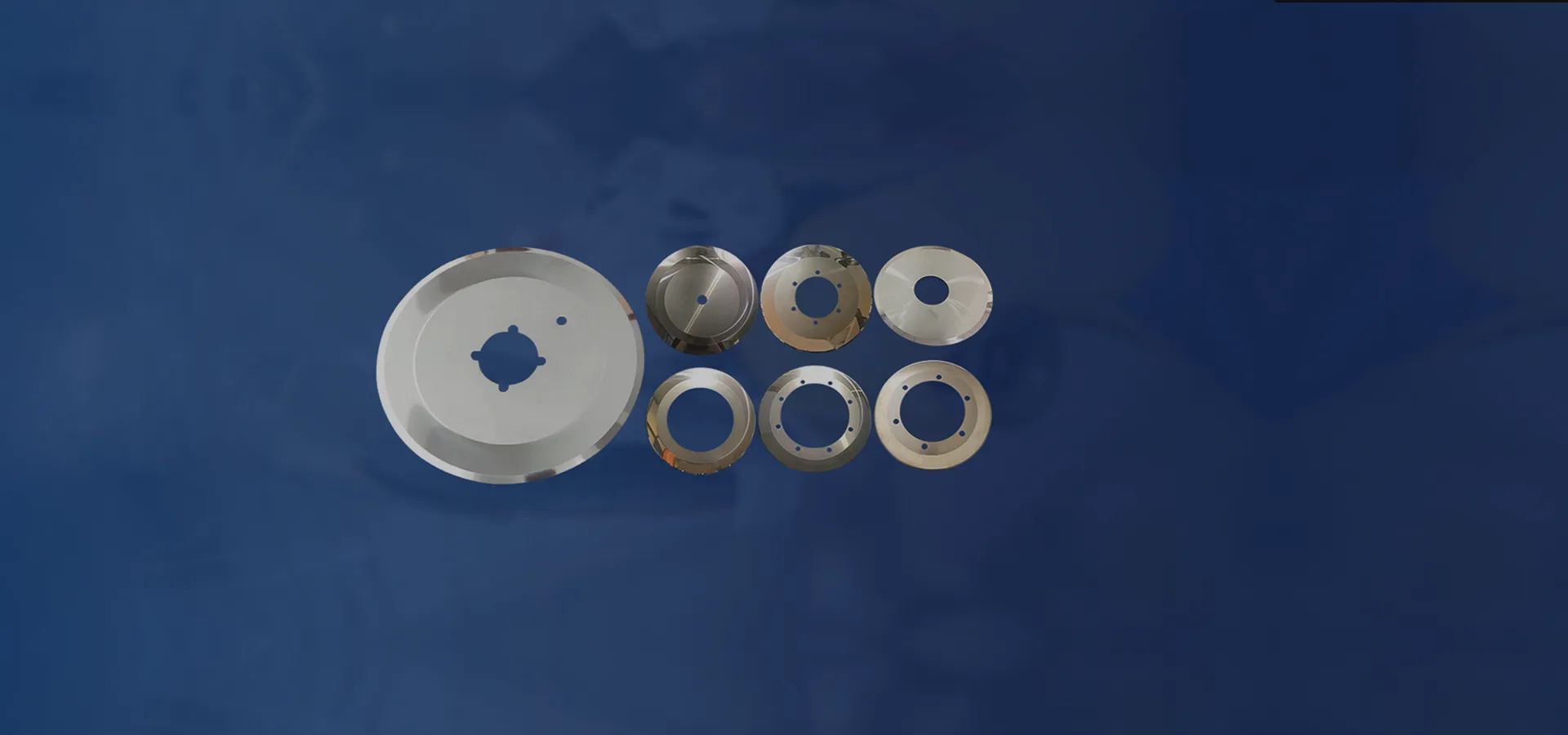

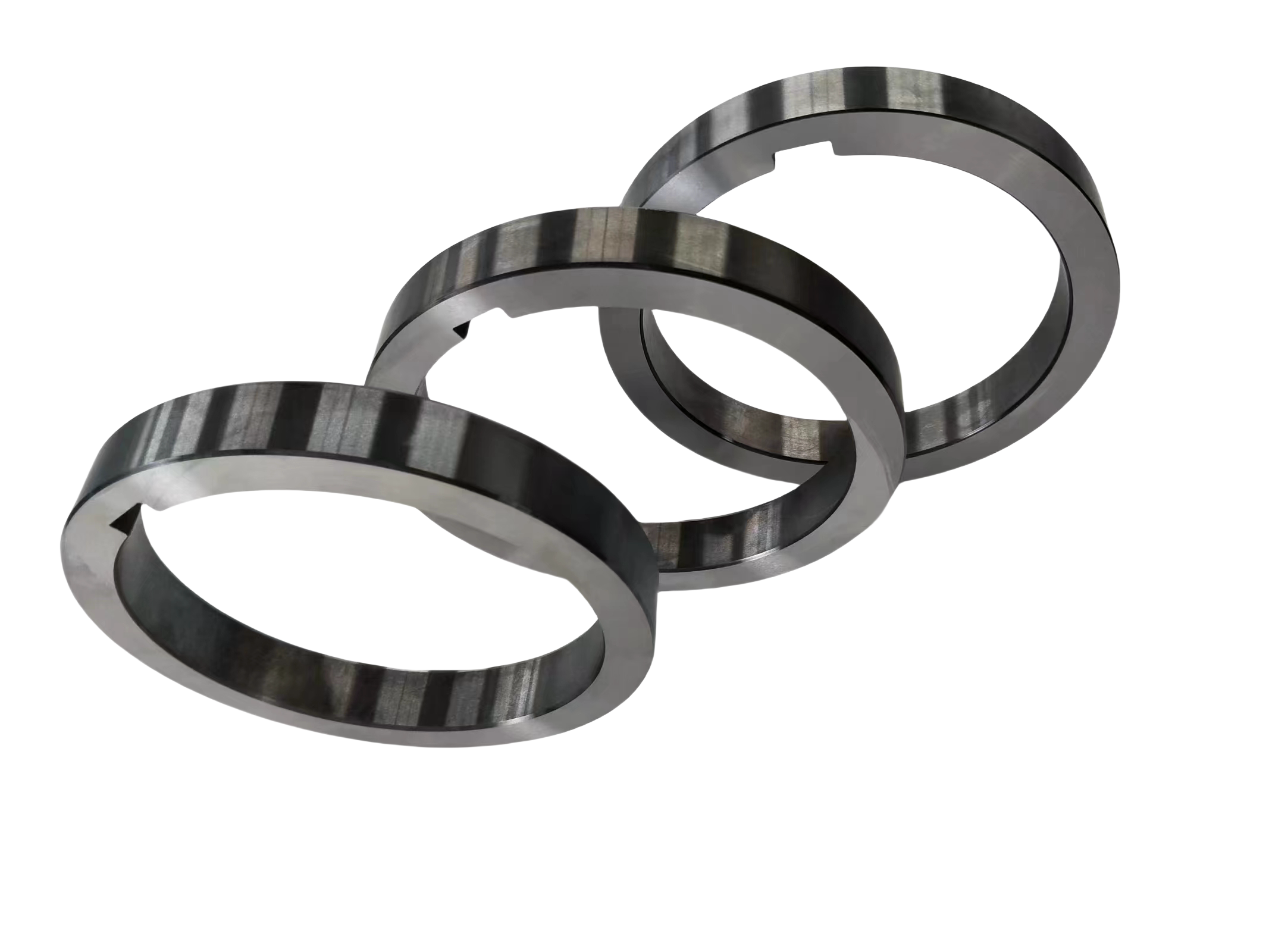

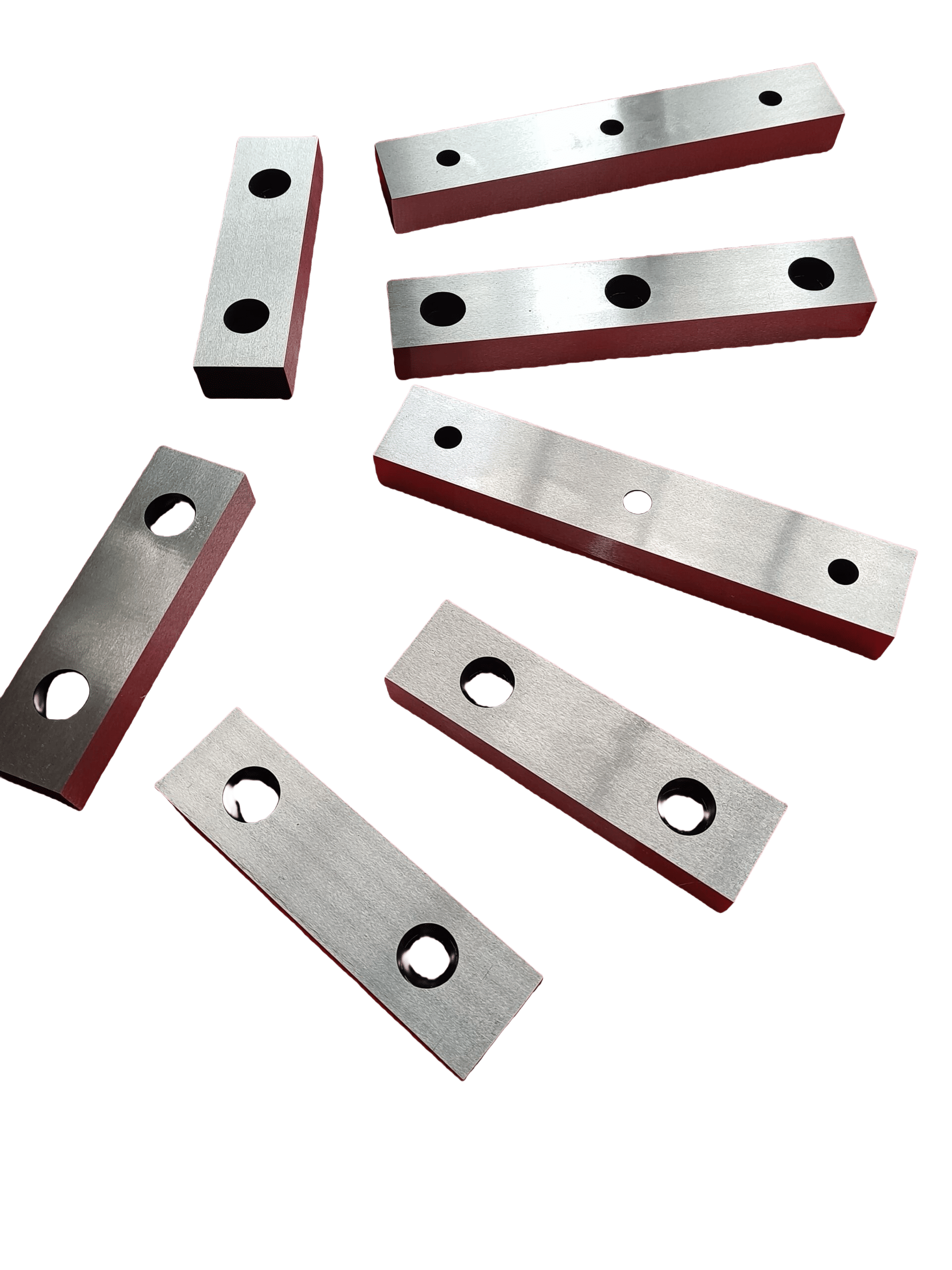

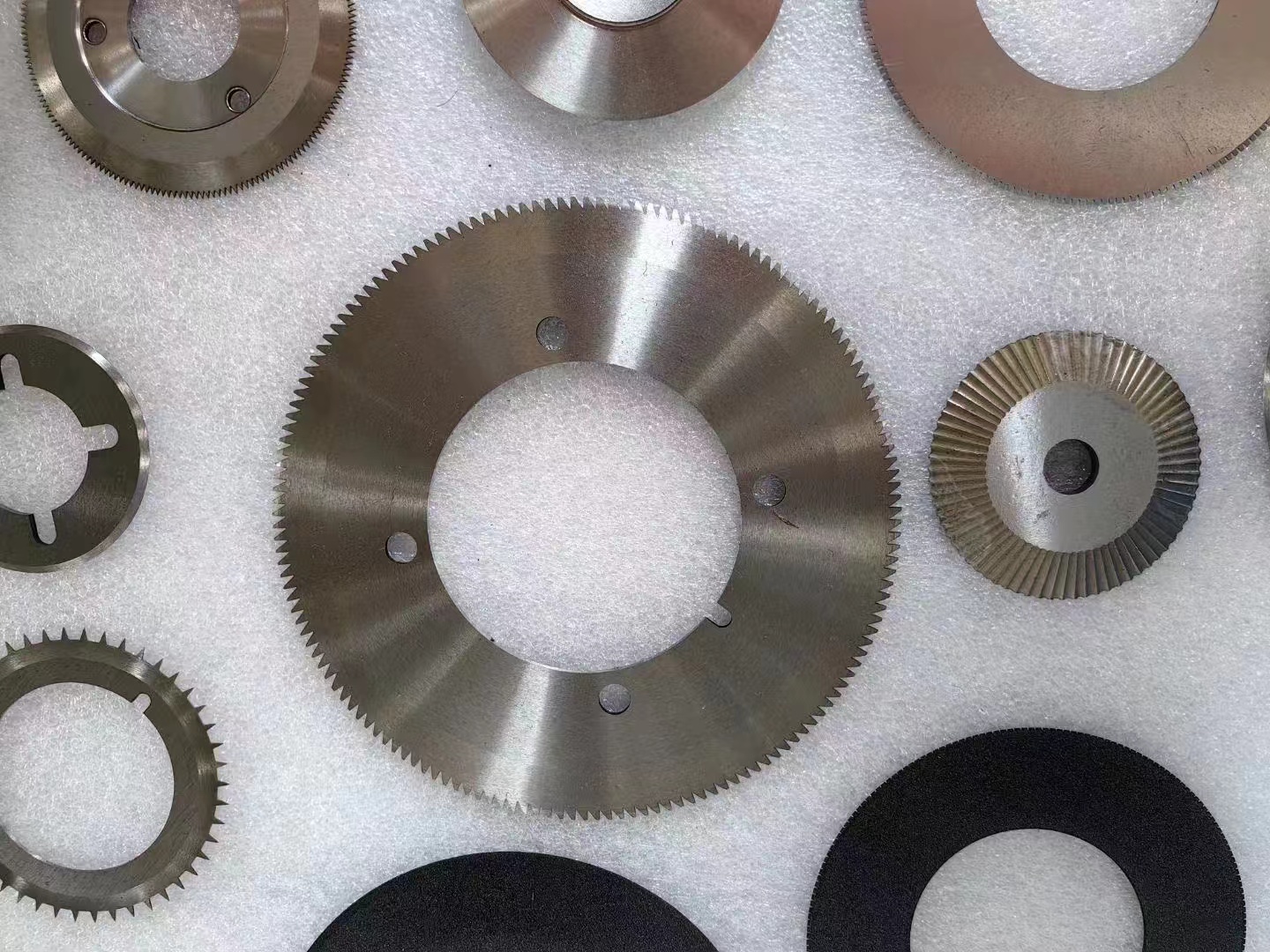

Categorías de productos de cuchillas

Principales productos recomendados

Centro de productos

Alta precisión de MISIQI

Acerca de MISIQI

Especializada en la producción de cuchillas de alta precisión.

Proporcionar asesoramiento adecuado a los clientes en materia de compras

Trabajadores con experiencia y responsables.

Equipos de alta precisión para la producción de cuchillas

Taller de producción

-

Medida de precisión

El mecanizado y la inspección de alta precisión mantienen los errores dimensionales dentro de un margen muy pequeño.

-

Mentalidad cero defectos

Las estrictas pruebas de calidad en cada paso contribuyen a garantizar un rendimiento estable en sus procesos de corte.

-

Mecanizado profesional

Dedicada a suministrar cuchillas de alta precisión y calidad para diferentes aplicaciones industriales.

Últimas actualizaciones

Noticias y eventos