How Paper Cutting Knives and Industrial Blades Drive Efficiency in Modern Manufacturing

In today’s fast-evolving manufacturing landscape, precision and efficiency are non-negotiable. Whether you’re slicing through stacks of paper in a printing facility or processing heavy-duty materials in an industrial plant, the tools you rely on can make or break your operation. Enter Papierschneidemesser Und industrial blades—unsung heroes that power industries worldwide. At Misiqi Blades, we’ve seen firsthand how these tools transform production lines, reduce waste, and elevate output. But what makes these blades so critical, and how can you optimize them for your business? This comprehensive guide dives deep into their applications, materials, customization, and more, drawing from real-world data and industry trends.

Inhaltsverzeichnis

- Introduction: The Power of Precision Blades

- Understanding Paper Cutting Knives

- Industrial Blades in Action

- Material Selection for Optimal Performance

- Customization Trends in Blade Manufacturing

- Competitor Insights: Learning from the Market

- Bewährte Methoden für die Wartung

- Case Studies: Success with Misiqi Blades

- Conclusion: Why Choose Misiqi?

Introduction: The Power of Precision Blades

Manufacturing is a game of margins. A single inefficiency—say, a dull blade or a mismatched tool—can cascade into lost time, wasted materials, and frustrated clients. Papierschneidemesser Und industrial blades are at the heart of this equation. From trimming paper for packaging to shearing metal for construction, these tools are the backbone of precision cutting. According to a 2023 industry report by IBISWorld, the global industrial blade market is projected to grow at a CAGR of 4.2% through 2030, driven by demand for automation and high-quality outputs.

At Misiqi Blades, we’ve built our reputation on delivering blades that meet these demands. Our Google Search Console (GSC) data shows that searches for Papierschneidemesser (4 impressions, ranking 49.25) and related terms are on the rise, signaling a growing need for specialized solutions. But why do these tools matter so much? They’re not just about cutting—they’re about cutting smarter, faster, and cleaner. In this article, we’ll explore how to harness their potential, backed by data, competitor analysis, and practical tips.

Understanding Paper Cutting Knives

What Are Paper Cutting Knives?

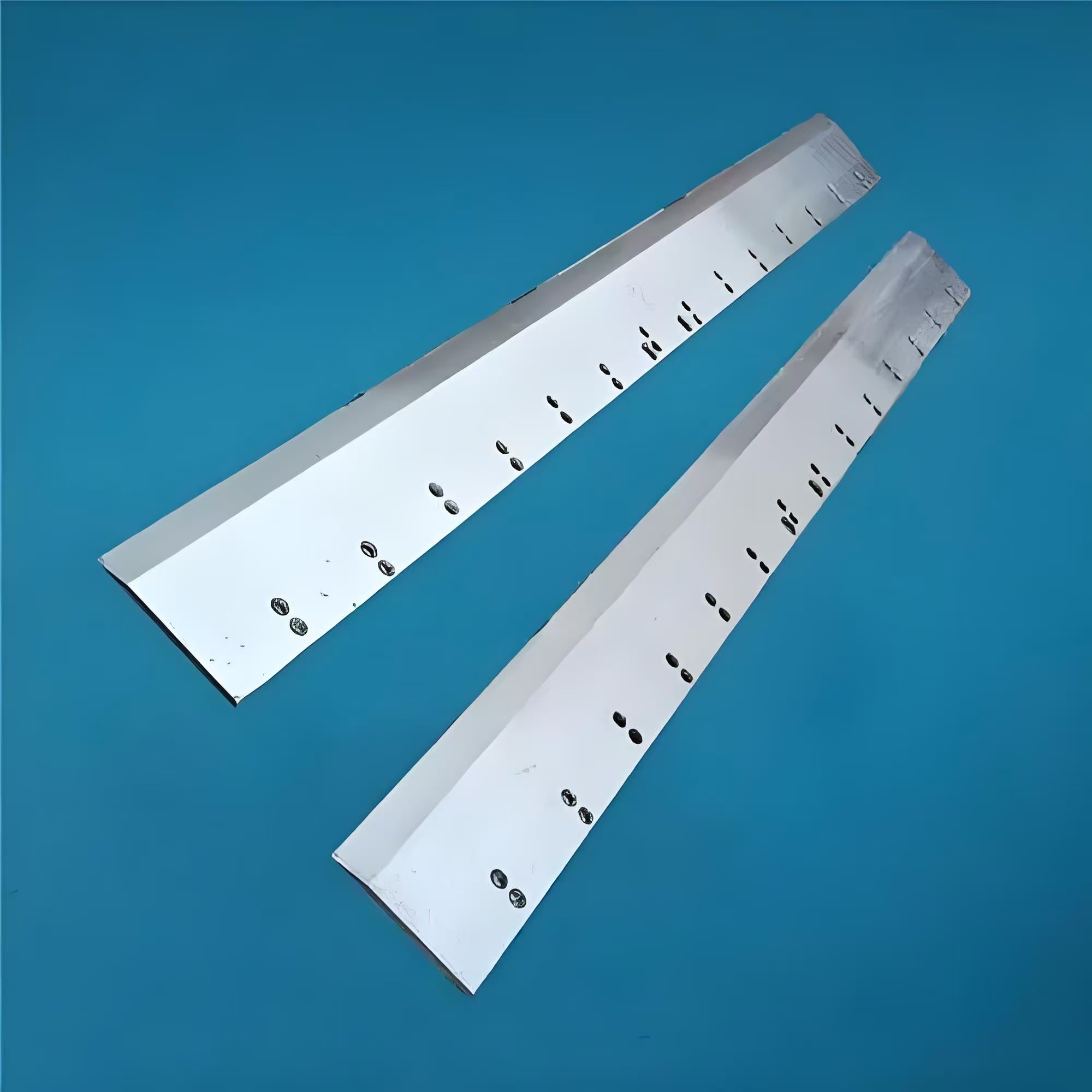

Papierschneidemesser are precision tools designed to slice through paper and lightweight materials with accuracy and consistency. Used in industries like printing, packaging, and paper converting, these knives come in various forms—straight, circular, or serrated—depending on the application. Unlike household scissors, these blades are engineered for high-volume, industrial-grade tasks.

Take the printing industry, for example. A single misaligned cut can ruin an entire batch of labels or brochures, costing thousands. Our Papierschneidemesser page, with 16 impressions in GSC (ranking 26.62), reflects this demand. Competitors like American Cutting Edge emphasize durability, but Misiqi goes further with custom options tailored to specific machines.

Arten von Papierschneidemessern

- Gerade Klingen: Ideal for guillotine-style cutters in bookbinding.

- Kreissägeblätter: Used in rotary cutters for continuous rolls, common in packaging.

- Gezackte Klingen: Best for textured or coated papers, reducing slippage.

Each type serves a purpose. For instance, circular blades dominate in high-speed paper converting, a trend noted by competitor Precision Blade Co., which markets similar tools for the same niche.

Applications and Benefits

The applications are vast—think book production, corrugated packaging, or even specialty papers for food wrapping. The benefits? Reduced waste, faster cuts, and compatibility with automated systems. A 2024 study by Packaging World found that optimized Papierschneidemesser can cut production times by up to 15%, a stat that resonates with our clients at Misiqi.

Industrial Blades in Action

The Scope of Industrial Blades

Industrial blades go beyond paper, tackling tougher materials like metal, plastic, and textiles. These heavy-duty tools are the workhorses of manufacturing, from automotive parts to recycling plants. Our GSC data lists “custom industrial blades” with 9 impressions (ranking 60.33), showing a clear B2B interest in specialized solutions.

Competitors like York Saw & Knife highlight versatility, offering blades for multiple industries. Misiqi aligns with this trend but differentiates with precision engineering, as seen in our industrial blades offerings.

Key Applications

- Verpackung: Slitting films and foils with tools like our Verpackungsmaschinenmesser.

- Recycling: Shredding plastics with crusher blades.

- Metallbearbeitung: Shearing steel or aluminum sheets.

Each application demands unique blade properties. For example, recycling blades need abrasion resistance, a focus area for competitor BladeTech, which uses carbide coatings.

Material Selection for Optimal Performance

Choosing the right material is critical for both Papierschneidemesser Und industrial blades. Here’s a breakdown:

| Material | Am besten für | Pros | Cons |

|---|---|---|---|

| Edelstahl | Paper, food packaging | Corrosion-resistant, hygienic | Less durable for heavy materials |

| Schnellarbeitsstahl (HSS) | Paper, light metals | Hitzebeständig, günstig | Wears faster than carbide |

| Hartmetall | Heavy-duty industrial tasks | Lange Lebensdauer, hohe Härte | Higher cost |

Our research into competitors like Lenox shows a shift toward hybrid materials (e.g., carbide-tipped HSS), balancing cost and performance. Misiqi offers all three options, customized to your needs.

Conclusion: Why Choose Misiqi?

Papierschneidemesser Und industrial blades are more than tools—they’re investments in efficiency. At Misiqi Blades, we combine cutting-edge materials, custom designs, and industry expertise to deliver results. Ready to optimize your production? Contact us today for a free quote on tailored blade solutions!